Sustainable Process Efficiency and How to Achieve it.

Globalization has imposed many changes on how a customer judges the value of a product. This shift in their behaviour has given way to a new business focus. Different approaches have been adopted such as the lean manufacturing system and the concept of sustainability. However, to implement these two simultaneously is easier said than done.

An apparel industry involves complex stages of production, each stage being exclusive in its techniques and methods, with myriads of other aspects to be considered. Adopting a systematic approach to every single stage is one way to ensure minimum wastage and efficient utilization.

A business model should adopt a continuous, iterative approach to achieve sustainable process efficiency. No matter how much you research and analyze the market process, you still need first-hand experience of what works and what fails. So, it’s best not to expect that you will be successful in your first attempt. Constant computation of figures and data and reviewing them will help you to achieve the desired sustainability.

Always remember, consistency is an important key to success. A sustainable framework is complex, to say the least. Hence you need to be very consistent with your strategies. The designs and executions should be valid and consistent. The process of evaluation should be strong and should generate consistent information to add to the value improvement programmes.

Here are 5 key things you must assure to achieve sustainable process efficiency :

Operation-aware process lifecycle :

This means, considering things from an operational standpoint. You shouldn’t be seeing things from the outside but from inside the activities. You can always map all activities and find the relations between them. You must identify the events that keep the process in motion, how one activity flows into the other. Once you are familiar with this map of activities, you can begin to gauge the operational processes and eventually control them in the later periods.

A user-oriented model

Once you have identified the activities, you can move on to define how the information about the process is perceived by each user, how the process will be executed, and how each task can be controlled to ensure an error-free operation. This is the stage where you can ensure that the required business rules and management are implemented in each stage of operations. Remember to clarify the expected results and how the same should be carried out across the organization.

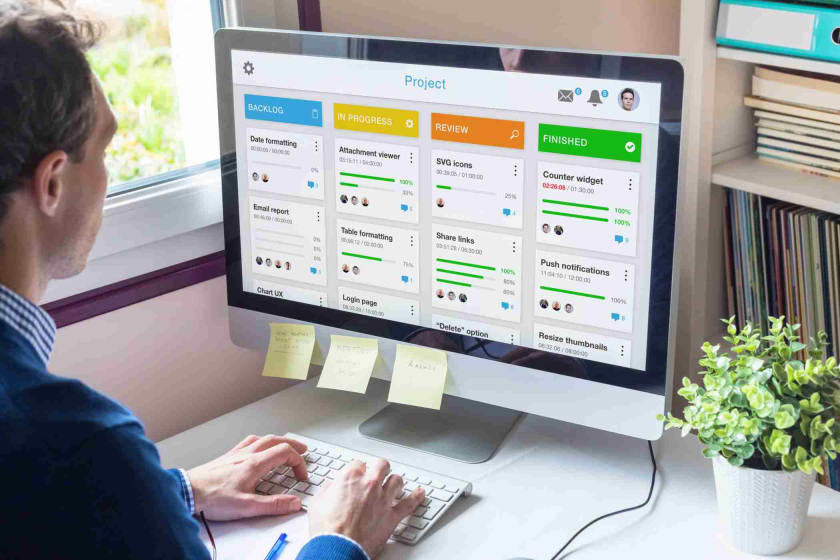

Real-time visibility

This can be done using dashboards that record ongoing activities and display real-life information about the same. This empowers you with real knowledge and information about your business which you can use to learn the trends and scope for improvements. This complements the consistency in mapping the operations and tracking the executions at each developmental stage. Real-time visibility also enhances the scope for drawing preventive measures as you get an immediate update about an issue.

Complete traceability

Modern business does this by using real-time PMS (Production Management System). By keeping records of everything, the activities, the time, and the outcome, you will only increase the chances of success. Tracking and tracing the business information means you will have the opportunity to review and examine the history to have an understanding of what worked and what didn’t. If you know what went wrong then you can prevent the repetition of the mistake and improve upon the past data. Consistency in data collection and management is a mandatory criterion to make complete traceability successful.

Activity driven assessment

This assessment should be based on clear-cut objective metrics and KPIs (Key Performance Indicator). The real-time information can be gathered from dashboards that display the targets and performances. This will allow you to identify the glitches that are obstructing the process, their origins, and probable solutions. Corrective actions and improvements can be carried out to restore smooth functionality.