A Beginner’s Guide to Working with A Sample Maker

A sample maker is a professional responsible for sewing the design for a fashion entrepreneur or designer. He creates the design from the designer's pattern to identify any issue before the pattern goes into production. Once a pattern is finalised, a prototype is made. We can say a model design that will work as the production base, aka numero uno. The sample maker works with pattern make and designer to sew samples. Here is a beginner’s guide to working with a sample maker. You can get your masterpiece by following this guide.

Purpose of a sample maker

A sample maker creates a clothing prototype for a designer. Their job is to stitch a garment based on the design and material supplied by the designers.

What does a sample maker do?

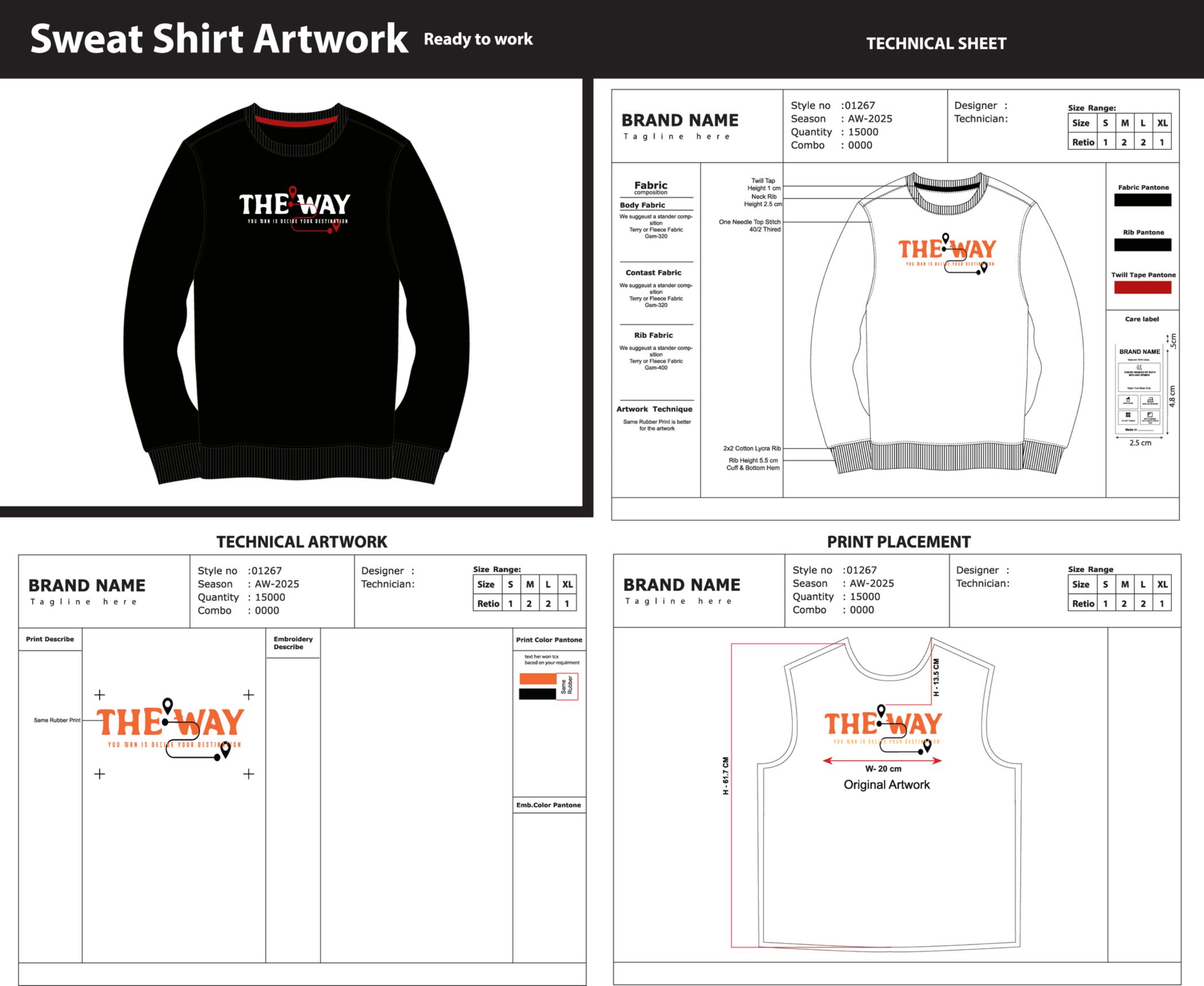

In simple words, a clothing sample maker makes or remakes a fabric based on a sample or design or pattern provided by the designer. Their role is crucial as a sample maker is one who translates the abstract ideas of a designer into a concrete form. He uses a tech pack and sample from the label and makes a production sample for a factory. These samples or prototypes are used as a reference to demonstrate to the client and convince him that a good result can be achieved.

For example, if you have an idea for a t-shirt design, you will approach a good sample maker of this t-shirt design field. You will tell him about your ideas, sketches, and expectations, and he will create a prototype or prototypes till you are satisfied.

Here sample maker will be required to do the following things:

- Interpretation of designer’s ideas

- Rough design

- Pattern creation

- Fitting of the patterns

- Revision and modifications

- Selection of the materials

- Final preparation of the end product

- Differentiation

- Interpretation of designer’s ideas:

A sample maker will discuss the ideas of the designer. The designer will talk about his expectations from the sample maker. The sample maker will chalk out those abstract ideas into a concrete form.

- Rough design:

The next step is the preparation of a rough design. It can be done using fabric or technical drawings. Without making a proper layout of the design, a designer cannot expect a sample maker to stitch his imagination. Various technical things are kept in mind while preparing these rough designs so that the prototype comes nearly perfect.

- Pattern creation

Based on the designer's requirements and patterns, a sample maker finalises the pattern for the prototype. Unique and elegant patterns are created that are appealing to the fashion audience. A designer's expectations at this step are very high and demanding because the pattern will make the piece stand out and unique.

- Fitting of the patterns

This roughly made prototype is then tried on different mannequins and models. Target end users kept in mind while checking the fitting of the patterns. Fitting an article is the most crucial aspect while manufacturing it, as, without a proper fit, the article will not suit properly to a human body.

- Revision and modifications

Now, the revision and modifications are made according to the designer's feedback and the sample users. These modifications are laid out according to the demand of the designers. Sometimes these revisions and modifications can be minor, but their redressal is very important for finalising the prototype.

- Selection of the materials

Additional accessories like buttons, zippers, laces, etc., are selected for the final touch to an article. The best quality of the accessories material is selected to avoid any after-sale negative feedback from the retailers or consumers. Sometimes the same design is made using different fabric types to get the best look out of different pieces of the work. A fine touch is given to the material to grace the item and make it different and appealing from other articles.

- Final preparation of the end product

After the final touch is given to the material, a sample maker will stitch the final piece and hand it over to the designer. This stitched piece will go to the manufacturing unit to produce the article at a large level. These items are then manufactured according to the demand of wholesalers, retailers, and consumers.

- Differentiation

All the above steps are followed for each graded size. Many times, the fitting may not look good on everybody's shape or size. So, these articles of clothing are tried on mannequins of different body types to get a better idea of the look of the design on the consumer.

Working with a sample maker

Every fashion designer or fashion entrepreneur should follow some basic steps to get the best work from a sample maker.

Step 1: Providing material

A designer should provide all the accessories, trims, and material to the sample maker. This material should be high quality, comfortable, and according to the prototype's needs. A designer should avoid providing a black and white fabric because it will be difficult to spot issues and photographs to fit comments.

The sample maker generally sews a quick sample called a Muslim to check the fit. Afterwards, this article will be tried by the models. The sample maker and the designer will discuss the adjustment if required. Proper feedback is taken from other people involved in the designing process.

Step 2: FinalisingFinalising the end product

After checking all the minor details of the clothing, like the pocket placement, stitching of the buttons, detailing, fine check, etc., the sample maker finally creates a perfect prototype. All the final details are also mentioned on the tech pack.

Things to remember while working with a sample maker

- Always go for a qualified clothing sample maker. The sample maker should have properly updated machinery to stitch the outside and provide a proper finishing inside for the design.

- The sample maker should have experience working with high-profile designer companies or production houses. Just home sewing will not work to create a masterpiece for the designers.

- The designer must go through a thorough check of the previous works of the clothing sample maker. A keen check should be done on the article's finishing, stitching quality, and detailed work.

- Always ask for an extra sample. This extra sample will be helpful for future references or a proof copy of the clothing sample maker.

- Check out the past clients of the sample maker and must take feedback from them. Only prefer a sample maker that has worked with designers who have vision like you.

- The sample maker should be well versed in the construction and seams terminology. Tech pack should reflect the instructions correctly.

- Sometimes the pattern maker or designer has a preferred choice of a particular clothing sample maker. If the sample maker cannot create the design or cannot use the right machinery for a specific detail, the final prototype must mention the issue on it.

- Now, this final prototype reaches the manufacturing units and factories. Further copies are made of these final selected products. These copies are called counter samples, and finally, the final production takes place.

Common terminology of the sampling process

- Sample room: A room in a factory dedicated to sample making.

- Fit Samples: Checks the fit and construction of your garment.

- Component approvals: Approving all the materials like fabric accessories.

- Colour print approval: Checking of colour combinations of the final production takes place.

- SMS: SMS is the abbreviation for Salesman samples

- GPT Samples: Garment production testing, testing of colour fastness, waterproof check, etc.

- Size set samples: To check the graded specifications.

Benefits of working with a sample maker

- Working with a sample maker makes communication easier. If you are a new designer or entrepreneur, you need to explain a lot about your ideas to a sample maker. An experienced sample maker will make your work easier and save a lot of time.

- If you are launching a new product or creating some unique designs or a masterpiece, a sample maker will help you realise your vision. He will provide you with his best skills and knowledge to create an outlandish and erratic creation.

- You can send the prototype for the final product to the manufacturing units and the factories without any worry, as a skilled clothing sample maker has made your prototype.

- A good sample maker will prepare a good tech pack for the designer. He will not leave any requirement of the designer unfulfilled or compromised.

- If you are thinking about a micro-production run, a sample maker will help you to lay down a vision and will help you to reach a big fashion audience by creating astonishing and magical creations through his skills.

To know more amazing details regarding fashion and the emerging fashion world, check out the official website of Fashinza.