5 Common Tech Pack Mistakes Made By Startup Fashion Designers

The tech pack is undoubtedly the most important document for a fashion brand in its production process. A minor mistake in the tech pack can lead to a lot of confusion in manufacturers' minds and unprecedented production cycle delays. Unfortunately, however, many startup fashion designers who are new to the clothing manufacturing process unknowingly make errors in the tech pack, which leads to serious issues for the brand. Let's have a look at some of these mistakes.

Missing specifications

All the types of measurements, i.e., flat and garment, and the dimensions of the finished product should be included in the tech pack. All these specifications will ensure that the final piece created by the manufacturer will have zero errors. However, startup fashion designers are new in the industry and often unsure of the exact specifications they want to include in the tech pack. They fear that they may end up adding a lot of information that will confuse the manufacturer, and therefore, in shortening up the tech pack, they often remove necessary details.

Not adding tolerance in the tech pack

Tolerance is the measure of the acceptable error in the final product. For instance, if the specifications in the tech pack ask the manufacturer to keep the bust measurement to 34", and the tolerance is ½ ", then in this case, the manufacturer can keep the bust measurement somewhere between 33½ "and 34½ ". If the manufacturer sews out of these limits, the product is discarded by the brand.

Therefore, to reduce the risk of getting the wrong product, one must always set a tolerance for garment manufacturers. This will save fashion designers from any uncertainty and build trust in the manufacturer. And suppose these tolerance limits are not included in the tech pack. In that case, the manufacturer will manufacture the wrong product, leading to quality control issues at the end of the manufacturing process.

Not mentioning the illustrations of point of measurement

A clear and concise illustration of each point of measurement in the garment will ensure that all the measurements by the manufacturer are taken from the right place, making the final piece accurate. Unfortunately, startup fashion designers often forget to add illustrations of a point of measurement in the tech pack. This makes it difficult for pattern makers at the manufacturing plant to interpret the design accurately and leads to a poor-quality sample that requires further revisions.

A lot of time and money is wasted during manufacturing. Therefore, one should always include illustrations for each point of measurement to avoid confusion in manufacturers' minds and to get better results in the development process.

Poor quality illustrations

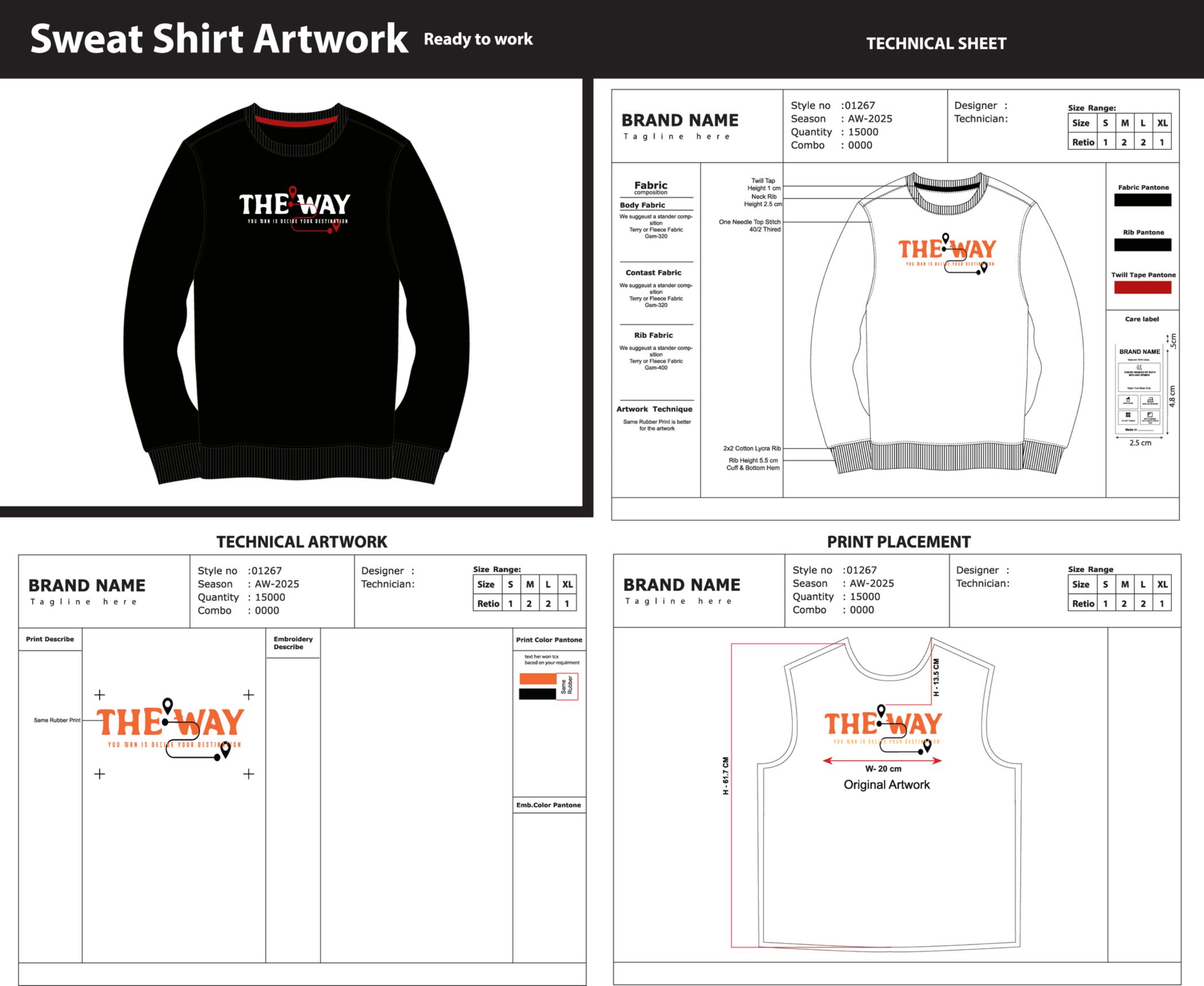

The most common mistake that startup fashion designers make is that they include low-quality illustrations in the tech pack. On the contrary, the tech pack should always have high-quality pictures, allowing manufacturers to analyze the design better. The purpose behind adding an illustration in the tech pack is to ensure that the manufacturers get a clear outline or line drawing of the product so that they can work to make a perfect product.

Missing construction information

Construction information includes information such as the type of seam, the kind of interfacing the manufacturer should apply, and what will be the perfect place for a buttonhole on the garment. Often, startup fashion designers miss out on these minute details, making it hard for the manufacturer to put the garment together, leading to a lapse in quality. Furthermore, it also leads to financial losses due to the waste of textiles and threads. Therefore, one should never miss the construction information in a tech pack.

Tips to avoid tech pack mistakes

Lapses in the tech pack can lead to manufacturing defects, eventually leading to financial losses for the company. Therefore, to avoid such situations, one must heed these tips.

Know what a tech pack includes

The most important thing that a fashion designer should be aware of is the major components of a tech pack. Along with the basic illustrations of the design and the references, one should include the following information in the tech pack.

- Article name and category

- Bill of Materials (BOM)

- Style Number

- Artwork

- Technical drawings

- Grading rules

- Specification sheet (measurements chart)

- Construction details

- Fabric placement and description

- Trims list

- Color definition

One can also include the following details if they want

- Testing requirements

- Packaging requirements

- Quality control requirements

- Name of buyer or supplier

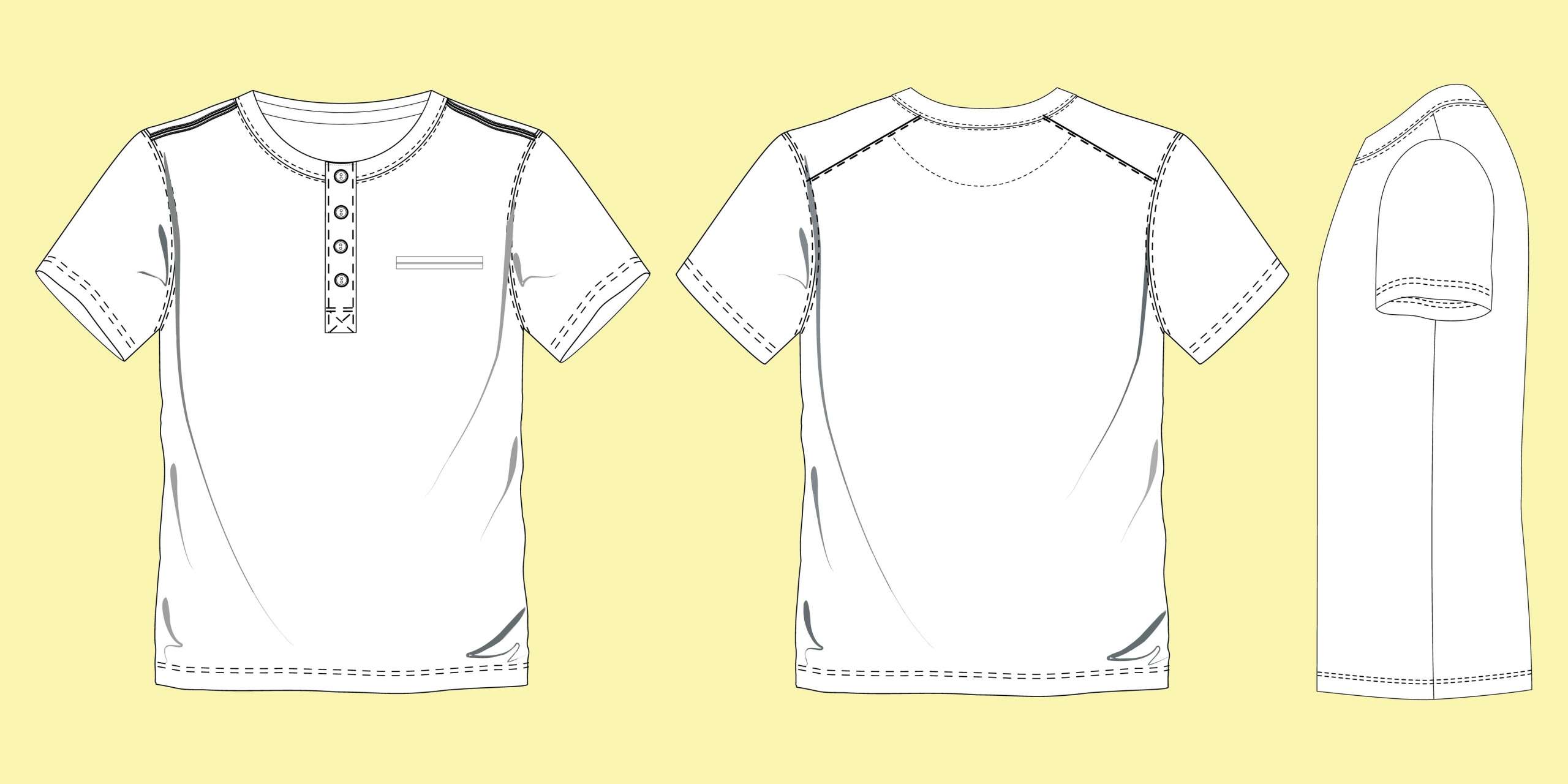

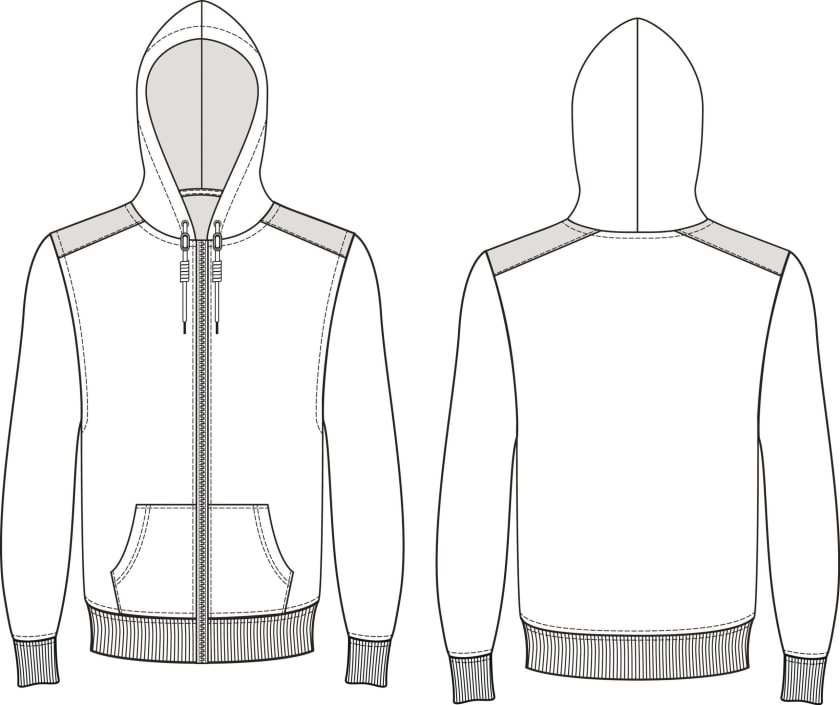

Use excellent technical drawings

The garment sketches might make one think they are sufficient, but the technical drawing is the real deal. Therefore, the tech pack should include a clear and detailed technical drawing of the front, back, sleeves, and side of the garment. In addition to these details, one should also include all the closeup features of the garment.

All the drawings in the tech pack need to have all the minute details, and one should ensure that they do not miss out on any seam or construction details. Moreover, one should also include illustrations of the placement of different elements of design, such as where the pocket should be and what is the right position of the buttons.

Pick the right format

Sending the tech pack in the right format is very important. For instance, if a brand is working with a factory located overseas, it needs to send the tech pack in a format that can be easily opened over the mail by the manufacturer. The best way to do it is to send the tech pack using Google drive. The manufacturer can then easily download the file and work on it.

Furthermore, one should ensure that the information is coherently put into the tech pack. All the information should be put clearly with the right font and font size. Finally, the tech pack should be divided into multiple pages to make it clearer for the manufacturer.

Detail is the king

The tech pack that a fashion designer intends to send out to the manufacturer should have every detail such as - the label, interlining, pocket, stitching, zipper, cuff, button, sleeve, sewing, and collar. One should also include a detailed measurement chart with the specifications. The exact color and thread count should be included in the tech pack to avoid confusion.

Fashion designers should include a grading chart with measurements for all the sizes they intend to get manufactured. They should then compare the brand's measurements to the industry standard to ensure that the products manufactured by the brand are not different in size from what other brands are selling.

Conclusion

The tech pack is the most important document that brands provide to garment manufacturers to get their products manufactured. One should avoid all the above-mentioned mistakes to avoid unnecessary loss of capital and brand value. Moreover, if you are a clothing retailer and want to get clothes from a brand that makes no beginner mistakes in its manufacturing process, then you can get in touch with Fashinza. Fashinza will help you in getting your desired set of clothes on time.