How to Create Seamless Dress Pattern Designing

From the color of a garment’s lining to the shape of its pockets, product designers know that details matter. Casting aside minor discrepancies can leave customers feeling frustrated and hurt a brand’s reputation. That’s why it’s important for anyone involved with design to understand how to develop and draft patterns. Technical drawings contain full-size details about clothing sizes and fit that help ensure patterns produce garments correctly.

What Is Dress Pattern Designing?

Dress pattern designing is creating a two-dimensional replica of your garment. Since patterns will be made based on specific requirements and take into consideration various fabrics, the pattern maker must consider much more than just the design in 2D. The pattern maker must consider how the design will be sewn into a textile so that the original design comes through while concealing any flaws or areas that might require alterations before applying them to the real fabric and creating the final product.

How to Create Patterns

Professionals make their dress patterns in a plethora of ways. What's popular these days is using a high-end computer program. Another popular process is using graphics tablets. But regardless of which pattern-making tool you use, all pattern development processes start with sketching an idea on paper first. While this basic sketch serves merely as a blueprint for the garment, several more steps must be completed to turn this basic notion into actual clothes that fit onto your body.

Types of Patterns

At this stage of production, three types of patterns are available:

1. Flat Pattern Drawing

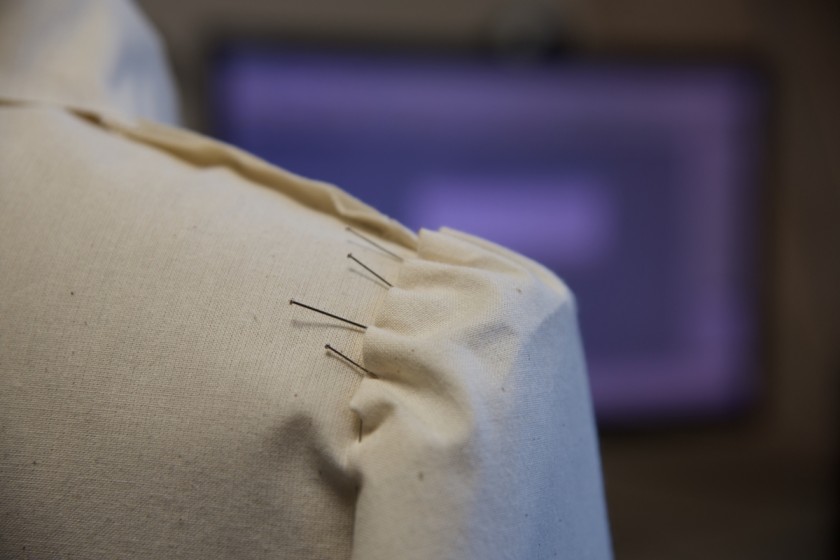

Flat pattern making is a vital skill for a professional designer. The process involves translating a basic pattern into a 3D shape with muslin fabric to help determine the fit of clothing. Flat pattern drawing helps to highlight the areas that require increased or decreased movement, keeping comfort in mind—it's all about fine-tuning.

2. Drafting

The goal of drafting is to create and design a viable and functional garment. Traditionally drafted garments are made with basic sizing guidelines and standard size presets from factories. Due to this, revisions may be issued to fix faulty patterns. Once the pattern and the basic shape of the desired garment have been finalized, it can then be used to make a muslin mock-up to test if everything fits correctly before sewing the final garment.

3. Draping

In the world of fashion, there's a well-known technique called draping. Draping, in simple terms, is when you take a cloth and put it over an object (sometimes called a 'model') to get an idea of what that garment might look like. The process of draping doesn't mean that these clothes are actually produced but rather gives designers an idea of how the outfit will turn out before they make any final decisions.

What Is Seam Allowance?

Seam allowances are a must for pattern makers. The seam allowance is a portion of a made garment that adds extra fabric between the cut edges to cover sewing mishaps and make the piece look well-made. Different dress styles have different seam allowances as it affects the appeal of the finished product. A common seam allowance used in commercial clothing production today is about 16 mm.

What Is Pattern Grading?

One of the most basic concepts of construction is pattern grading. This process involves taking a sample size, usually with instructions on how to modify that sample into different sizes that are larger or smaller. Pattern grading just makes simple changes to the original shape of your garment rather than creating something completely new.

Methods of Pattern Grading

1. Cut and spread method

Cut and spread is a quick and easy way to grade your patterns up or down. All you need is a ruler, pencil, scissors, and measuring tape!

2. Pattern shifting method

Pattern shifting happens when a pattern is moved around by an equal distance in all directions. Designers then repeat the pattern to get the same effect as the spread and cut method.

3. Computer grading method

Computer grading is the most efficient approach. It basically digitizes the "cut and spread method" and "pattern shifting method."

Technology and Pattern Designing

Designing for products using technology like computer-aided design (CAD) is becoming easier. This allows designers to develop designs much faster than previously possible. These types of software can be used in both large and small-scale design projects that are related to designing patterns for clothing or any manufacturing industry.

To keep up with the growing industry trends, businesses can benefit from updated software to understand how to develop products based on digital pattern creation. Companies need to take advantage of the latest innovations that allow them to increase efficiency and productivity.

Challenges Faced in Dress Pattern Designing

Pattern designing can make or break a business. Specifically, fabric choice can be a headache for pattern makers—since even slight differences in the fabric lead to varying degrees of drape and shrinkage, which can cause problems with fit and look. A tight or loose fit may indicate an entirely different style than what was originally intended, which will affect the bottom line. So it's best to find ways to minimize risk at all levels right from the start.

Importance of Professional Dress Pattern Designers in the Fashion Industry

Pattern makers are the boots-on-the-ground backbone of the fashion industry. While designers may tend to dream big with fantastical ideas that never actually come to fruition, it is the job of a pattern maker to take these wild creations and transform them into products while keeping the designer's vision in mind. Pattern makers have to juggle both pragmatism and creativity as both skill sets are required for their jobs. They are truly imaginative individuals who bring what many would consider dreams to ultimate fruition!

Conclusion

While it seems like designing a dress pattern is a fairly straightforward process, there is a lot of work that goes into it. Creating patterns for clothing production is a prominent art. Setting each pattern properly will ensure that the clothing fits the desired specifications, preventing any mishaps or accidental mistakes. Dress pattern designers bridge the gap between conception and production, making this process straightforward for both the brand and manufacturer.

When you need design and sourcing help for your fashion brand, we at Fashinza are there to assist you. We work with fashion brands like yours and connect you with amazing apparel manufacturers in the industry so that you can stay ahead of the curve. If you're also looking to manage your own design process, we can help with that too! Our skilled team takes ownership of the complete production, from design through delivery, to ensure you always get what you pay for and much more when it comes to your orders.