Importance of Material Blend While Buying a Waterproof Fabric

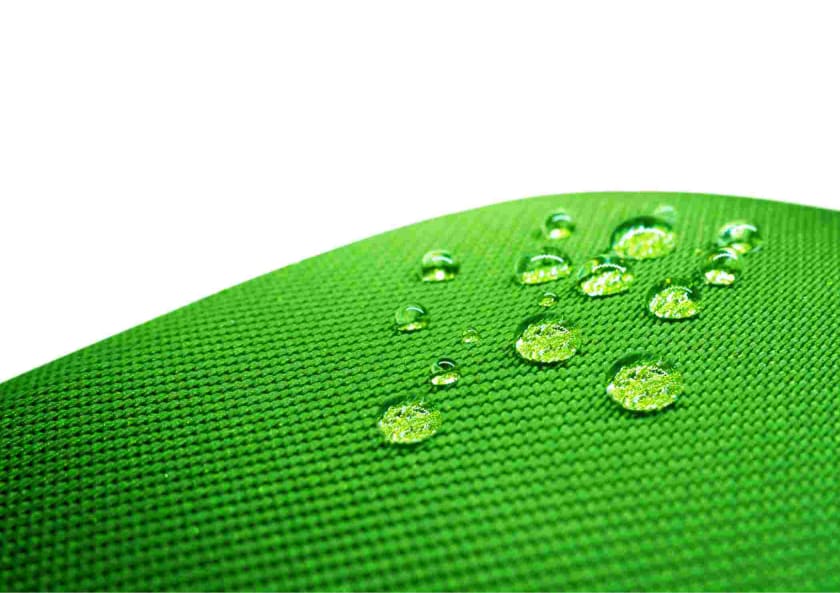

We all like to use waterproof material especially if we live in an area that receives a lot of rainfall or snow. Often natural or synthetic fabrics like cotton, silk, wool, polyester, or nylon are coated with a waterproof material like rubber, wax, polyvinyl chloride (PVC), or polyurethane (PU). Even silicone elastomers or fluoropolymers that are used less than the above-mentioned materials are used to convert a normal fabric into a waterproof one.

Fabrics that are used in waterproof jackets, umbrellas, baby spreads (to stop urination from spoiling the mattress), etc., include polyester, nylon, and pongee materials. Over the years, the fabric manufacturing industry has evolved manifold and has come up with excellent blended waterproof fabrics. Since these fabrics have excellent waterproofing and UV protection capabilities, they are extremely popular amongst buyers.

How is Waterproof Fabric Made?

A layer of waterproof material is chemically bonded to the outer layer of a natural fiber like cotton. It is known as laminated cotton. This outer layer is known as the membrane. Two types of membranes are used to manufacture waterproof, breathable fabrics (WPB). The membrane of polyurethane (PU) and membrane of expanded polytetrafluoroethylene (ePTFE developed by Bob Gore in 1978) are the two types of membranes used in this process.

Which Blends Are Best for Creating Waterproof Fabric?

- Waterproof Polyester: Polyethylene terephthalate (PET) or polyester is known for its durability and resistance to chemicals. Since it does not shrink or stretch, it is ideal for making umbrellas, jackets, and other waterproof items.

Spun polyester which is the fabric of choice for manufacturing umbrellas is a synthetic fabric. Normal polyester fibers are spun into yarn and sometimes it is blended with other synthetic fibers to increase their strength and make polyester waterproof.

- Waterproof Nylon: Nylon is water-resistant and many manufacturers use tightly woven nylon fabric to manufacture waterproof nylon. They use silicone sprays over the waterproof material to make it completely water-resistant. This material even blocks the harmful ultraviolet rays and it dries quickly too.

The fabric manufacturers use patented fabric technology and blend multiple fabrics to make them further water-resistant. An extra layer of polyurethane (PU) on the Teflon surface is used as a membrane. Since Teflon makes fabrics resistant to oils too, they are preferred in manufacturing waterproof nylon fabric.

- Waterproof Pongee: Pongee was originally invented in China and its tightly woven threads give the texture of cotton. The threads are unbleached and offer better water resistance to materials that are blends of polyester or nylon.

- Waterproof Satin: Natural satin fabric is made from silk whereas synthetic satin is chemically manufactured in the factory. Due to the shiny surface, it looks good when jackets, umbrellas, and other waterproof items are made of it. A blend of synthetic and viscose fibers is used for this purpose. A viscous organic liquid is chemically bonded with the fiber. Sometimes a blend of viscose rayon is also blended to manufacture this material.

I personally like satin waterproof material a lot due to the smooth texture. It looks shiny and gives a nice look to the umbrella that I use. The floral prints look very attractive. Even jackets made of satin blended waterproof materials are comfortable and look extremely attractive.

Why is Material Blend Important While Buying Waterproof Fabric?

Material blend for waterproof fabric is extremely important because it determines the texture, touch, and feel of the fabric.

- All-weather fabric: Waterproof polyester fabric is often considered an all-weather fabric when blended with cotton. If the percentage of cotton is around 40% in the yarn, the material is breathable and soaks sweat. Hence, it can be used to manufacture jackets and other wearable items and the user will not feel uncomfortable during the summer months. The fabric absorbs the sweat and keeps the user relaxed.

- Durability: All the above-mentioned types of fabrics are extremely durable. Since polyester and nylon are man-made synthetic fibers, their longevity and tensile strength are very high. They can withstand wear and tear and last very long.

- Texture: The touch and feel of any material are extremely important when you are choosing it for clothing items. If the fabric feels scratchy, coarse, or stiff, the user will not feel comfortable while wearing it. Spun waterproof polyester and satin materials are soft to touch and hence users prefer them over many other blends for jackets and other wearable items.

Polyester and cotton blends are preferred over other blends for manufacturing waterproof jackets, raincoats, and aprons. - Wrinkle Resistance: Amongst all the popular blends of waterproof materials, polyester material has the best resistance to wrinkles and shrinking. Hence even umbrellas made of polyester blends are preferred by users as it does not shrink much when kept in a closed position.

When polyester waterproof material gets wet, it does not lose its shape. Even when it is washed or dried, the shape and texture remain almost the same. Jackets made out of blended polyester and blended nylon materials can be easily washed in washing machines. - Colorfast: Yarn made of waterproof polyester and nylon fabrics can hold color very strongly. Hence unlike natural fabrics like cotton and silk, they do not bleed. That is another reason why users prefer to buy polyester or nylon blended clothes. They can be worn in rains, snow, sleet, or any weather conditions and the user will feel warm and cozy. If they get wet, the color will remain as is.

So what are you waiting for? Enjoy the rains and snowfalls with jackets and overalls made of waterproof materials.