Polymers: Everything you need to know

Introduction

Polymers in the textile industry refers to any class of natural or synthetic substance which is made up of very large molecules which are multiple of several chemical units called monomers. Monomers have the ability to combine with similar looking molecules and this process is called polymerization. Silk Sarees use bright polyester which is cheap and durable. Examples of polyethylene include sandwich bags and soft drink cups. Curtains, tygon tubing and pipes showers have poly vinyl chloride. Chewing gum is an example of poly vinyl acetate.

Polymers can be of two types - natural and synthetic. Synthetic ones are composed of petroleum oil and are man-made by scientists and engineers. Examples include teflon, epoxy, polyethylene and polyester. Natural ones are extracted from nature that include natural rubber, starch, proteins and cellulose. In the textile industry, mainly nylon and polyester polymers are used. Both these polymers are used in production of clothes in the textile industry.

Textile fibre polymers used in clothes provide an understanding of how the fibres behave and how they are dyed. Moreover, their strength, colorfast properties and shrinking ability can also be determined. Generic Fibres used to make clothes include silk, cashmere, ramie, wool, linen, cotton, polyester, nylon, rayon, olefin and acetate. Cotton, rayon, ramie and linen are made up of cellulose and wool and cashmere are made up of alpha keratin.

History of Polymers in Clothes

Clothing dates back to roughly ten thousand years ago, when animal skin, hair, and leaves were the most common materials used to cover the human body. The industrial revolutions coincided with the growth of garment materials. Cotton, wool, silk, and a variety of other natural resources were utilised to make garments before the polymer factory was well-established. Today's advancements in science and technology provide customers with new sorts of materials that have unique and useful features such as softness, stretchiness, high strength, and, most significantly, low cost. Synthetic polymers, such as polyesters, polyacrylics, and polyamides (nylon), may be easily modified from the smallest synthetic unit, unlike naturally occurring polymers such as cotton and wool (monomer).

Textiles are used to make a wide range of consumer goods, including clothing, carpets, towels, bags, tablecloths, blankets, and mattresses. Filters, industrial geotextiles, upholstery, conveyor belts, heavy-duty tyres, seat coverings, seat belts, air bags, parachutes, fishing nets, optical fibres, packaging textiles, insulation and roofing materials, ribbons and tapes are all examples of technical or industrial textiles in use. Textiles are also utilised as reinforcements in composite materials like fibreglass and carbon fibre reinforced plastics. Cotton and polymers are the two crucial substances used to make clothes.

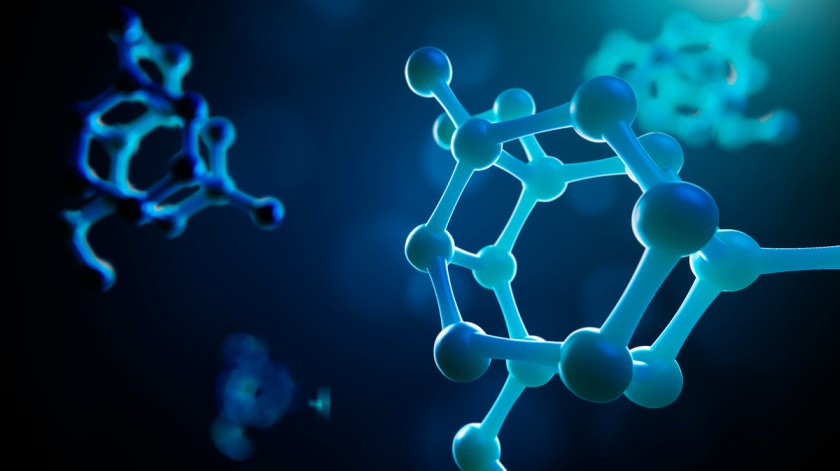

The most common way to classify polymers is to split them into three groups: thermoplastics, elastomers, and thermosets. Plastics that change into liquid when heated are known as thermoplastics. These are easy to mould and are utilised in the manufacturing of clothing. Elastomers are crosslinked rubbery polymers (i.e. rubbery networks) that can be stretched to extreme lengths (e.g. 3x to 10x their original dimensions) then swiftly return to their original dimensions once the stress is removed. Thermosets are often stiff materials and arc network polymers with a high degree of crosslinking that restricts chain mobility. As a result, procedures like compression moulding, which need very little flow, are frequently used to turn them into artefacts.

Use of Polymers in Clothes and Technology Advancement

Aside from general research into the molecular structure and principles of actively moving polymers, recent developments in textile fields such as fibre spinning (including wet spinning, melt spinning, and electro-spinning), fabric manufacturing, shape memory finishing technology, and water vapour permeability research are highlighted. To present, the majority of textile applications of Actively Moving Polymers (AMPs) have focused on thermally induced Shape Memory Polymers (SMPs). Multi-responsive SMPs that respond to light, electricity, and moisture, as well as multi-functional SMPs that incorporate anti-bacterial function and health care, may be more appealing in smart textile applications. Liquid Crystalline Elastomers (LCEs) are known for shifting shape, but their high cost and complicated manufacturing have limited their use. With the development of these technologies, there is ample inspiration for scientists to improve fabrication technology and reduce cost of AMPs.

Technology in this field is rapidly growing nowadays. The way polymers and textiles are made is changing for the better. Engineers and scientists working in polymers and textiles are focused on producing more sustainable goods as concerns about the impact of climate change grow. Businesses with sustainable goals have better chances of profits in the future.

Chemists at McGill University's Pulp and Paper Research Center in Quebec, Canada, are developing recyclable, biodegradable textiles utilising wood-based cellulose fibres. Carbon disulfide, a hazardous chemical that may cause acute and chronic poisoning, is commonly used in the production of rayon fibres. The McGill technique eliminates the volatile liquid and produces fibres that are comparable in strength to rayon. Such methods are being adopted by various textile industry players throughout the world. Customers feel a sense of connection with companies believing in sustainable fashion.

The growth of Smart Textile Industry

Smart textiles are perhaps the most potential area of growth in this business. Wearable electronics that can detect, respond, and adapt to changing environmental circumstances range from basic sensors to those that can sense, react, and adapt to changing environmental conditions. Advanced textiles offer a wide range of uses, including fire, weather, and chemical/biological agent protection. Wearable sensors can detect body temperature, heart rate, blood sugar, and more, making them particularly valuable in healthcare, sports and fitness, and everyday use. Some of the other smart clothing global companies are Adidas, LifeSense, Clothing+ and DuPont.

According to a recent analysis released by SBWire, the worldwide smart-textile market is expected to develop at a compound annual growth rate (CAGR) of about 25% by 2030.

Google, which recently worked with Levi to produce a smart denim jacket that responds to touch gestures on its cuff, is one of the market's key players. The garment connects to a smartphone, and orders such as answering a call or skipping a music are sent by swiping and touching the cuff.

AiQ Smart Clothes is a Taiwanese firm that specialises in athletic clothing. Through conductive, fiber-based electrodes, its clothing can monitor heart rate and operate as an electrocardiogram (EKG).

Advantages of Polyester vs Natural Fibres

In polymers, the life of the finished product is longer and the fabric strength is higher. In natural fibre, it is lesser as compared to polymers. The outlook of polymers is better as compared to natural fibres. Polymers have a better scope in elaborate styles and designs such as semi-dull, micro, super bright, easy dye, biocomponents and cationic dyes. If you use natural fibres, there is less variety available. The cost of fabric manufacturing in polymers is less as compared to natural fibres. Moreover, polymers have high operational advantages as natural fibres need humidification, high speed and better preparation. Wet process of fabric is tough in natural fibres. Even the daily maintenance of natural fibre is high as it requires more washing and ironing.

Disadvantages of Polyester vs Natural Fibres

Initial cost of raw material is higher in polymers and less in natural fibres. During extreme weather conditions natural fibre is more comfortable to wear as compared to polymers. Polymers have a less moisture absorbing property as compared to natural fibres.

What are Jeans and T-shirts made of?

Plant resources, synthetics, and even proteins like silk and wool may all be used to make polymers for clothing. The majority of polymers found in clothing have one thing in common: they are fibres. To begin with, these blue jeans and t-shirts are made of cotton, which is mostly composed of cellulose. Wool, which has a protein called keratin, may be used to make sweaters like these. By the way, your hair and fingernails are in great shape. Acrylics, like polyacrylonitrile or RayonTM, can also be used to make sweaters. Socks and sweaters share a lot of the same polymers. Polymers like nylon (which feels dreadful on your skin) and cotton (which is formed of cellulose) are also present.

A Step towards Sustainability within the Textile Industry

The relevance of textile recycling and reuse must be recognised by both the textile industry and consumers. Only 1.2 million tonnes of textile made from virgin building blocks are reused, whereas 0.73 million tonnes are recycled, according to data collected in a scientific review. This is a step in the right direction toward a more sustainable future for textiles, but more work is needed to identify better ways to save the material and reduce waste and pollution. In order to further establish a closed loop on textile manufacturing, customers' attitudes toward reusing, rather than purchasing, and recycling, rather than needing newly-made material, need to shift.

For more information, browse Fashinza.