How To Print design on fabrics? Methods, Costs, Manufacturers

Fabric printing has been around for ages. It all began with the popularity of “Chintz” fabrics in the 17th century in Europe. Interestingly, the cloth, at that time, was imported from India. These fine cotton textiles were painted and dyed with vibrant flora and fauna. Since then, there was no looking back.

A recent report by Market Study mentions that the worth of the global textile printing market reached $2524.54 million in 2020. Moreover, the numbers are expected to grow considerably in the next five years. Adoption of design flexibility, increasing popularity of soft signage, and growing digitalisation in textile printing are some of the major factors that are driving this industry to the zenith. Needless to say, this industry is on a boom and denies slowing down anytime soon.

Fashion brands should consider this as a golden opportunity to shine in the crowd. Investing in fabric printing can yield unlimited profits for them. Entrepreneurs who aim to make it big in this industry can also consider stepping into the fabric printing business. But before that, they need to understand everything about print design on fabric, methods, costs, and manufacturers. It is what our today’s blog post will be about.

Stamp Printing

It is one of the easiest fabric printing methods so far. As the name derives, stamp printing is done with the help of stamps. These stamps have designs pasted on them. They are dipped in colour and applied to the fabric. However, stamp printing is one of the oldest methods of textile printing. But its printing is limited to basic motifs only. Designers cannot rely on it for intricate designs.

Pros

- Cost-effective

- Quick fabric printing method

- No need for machinery

- Perfect design every time

- Ideal for small runs

Cons

- Inconsistent quality

- Not suitable for elaborative patterns

- Not useful for large scale printing projects

- Only one print per stamp

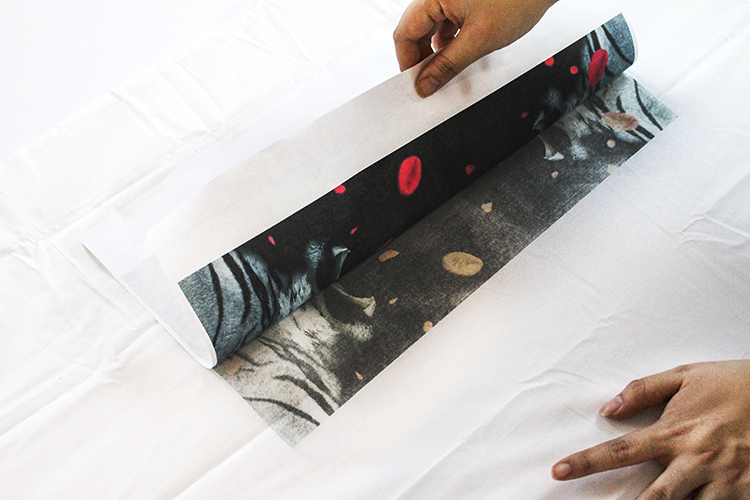

Transfer Printing

It is an upscale textile printing technology that is used to print beautiful patterns on the fabrics. This printing is done with the help of a special paper that is readily available in craft and stationery shops.

Designs are printed on these papers with the help of advanced and high duty machinery. These prints are transferred to the fabric with the help of steam iron machines. Please note that this printing method leaves a glossy film or texture on the fabric. This surface can peel, crack, or fade with multiple washes.

Pros

- Profitable printing technique for small businesses

- Perfect prints

- Easy to operate

- No need for special equipment

Cons

- Cracks, peels, and fades over time

- Not a durable fabric printing method

- Leaves a shiny film on the fabric

Pigment Printing

Pigment printing has been in the industry for years. It is a special textile printing method where colours are added in different moulds. It leaves an imprint of the desired design on the fabric. A special adhesive is also mixed with the colours to help them stick to the fabric permanently. The best part about pigment printing is that it can be done on both natural and synthetic fibres.

Pros

- Excellent fabric printing methods for permanent and bright designs

- Quick results

- Cost-effective

- The colour sits on the fabric and is not embedded in it

- Ideal for colour-resistant effects. For instance under reactive and azoic dyes

Cons

- Can be a time-consuming technology for multi-colour designs

- Highly labour intensive. Not suitable for small runs

- Creates high wastage

Screen Printing

Screen printing is another popular print design on fabric technique that is done with the help of ink, a mesh screen, and a squeegee. It is an analogue fabric printing method that presses paints through the porous mesh screen to the fabric and forms a print. The best part is this process can be performed both manually and mechanically.

It makes it an ideal fabric printing method for both established and start-up enterprises. There are two variations of screen printing; flatbed printing and rotary printing. Flatbed screen printing is costlier. Whereas, rotary screen printing is a mechanical version of traditional screen printing.

Pros

- Can be used in printing on both dark and light coloured fabrics

- Screen printing can be used in large patterns

- Screen printed fabrics enjoy huge popularity in the markets

Cons

- It is a labour-intensive method

- Expensive than other fabric printing methods

- Not suitable for multiple gradations and variations of colours

Reactive Printing

It is a heat-activated fabric designing method that is done on pre-coated fabrics. The idea is to paste a reactive dye on the top of the fabric with a special adhesive, and apply heat to permanently stick it to the fabric.

It makes it an ideal fabric printing method for both established and start-up enterprises. There are two variations of screen printing; flatbed printing and rotary printing. Flatbed screen printing is costlier. On the other hand, rotary screen printing is a mechanical version of traditional screen printing.

Pros

- Excellent colour vibrancy

- Ideal printing option for natural textiles

- Forms a chemical bond between fabric fibres and reactive dyes

Cons

- Needs pre-treatment and post-treatment

- Can prove to be an expensive fabric printing method

- Technical competence is a must to perform reactive printing

Dye Sublimation

It is a multi-step fabric printing process that offers some of the best printing results. How does dye sublimation work? Designs and patterns are printed on a special thermal transfer paper or dye sublimation paper. Both pressure and heat are applied to transfer this design to the fabric.

Deep colour infusion technology is used to perfectly bond the design and colours with the fibres of the textile. Special water-based inks are used in this fabric printing method. It makes it ideal for intricate patterns and designs. The best part about dye sublimation is, it does not interfere with the softness of the fabric.

Pros

- Prints and colours remain intact for years

- Eco-friendly fabric printing method

- Suitable for both small and larger runs

- Does not leave any residue or texture on the fabric

Cons

- Not suitable for natural fabrics

- Expensive printing method

- Demands experience and an in-depth knowledge

Cost of Fabric Printing

Fashion professionals and entrepreneurs who are considering a transition into the fabric printing industry should have a fair idea about its overall cost. Although the cost of all the fabric printing methods varies from manufacturer to manufacturer. But we have identified three major factors that can impact the total cost of fabric printing.

- The fabric printing method

- The type of ink or dye used in printing

- Is the printing method labour-intensive or machinery-based?

Manufacturers

Silk, cotton, polyester, or nylon, not every textile type is made equal. Every fabric material needs a certain kind of ink chemistry. Therefore, it is crucial to pick the right fabric printing machine for the right project. Here is a list of the top 5 manufacturers that roll out the most advanced fabric printing machines in the world.

- Durst Group

- Konika Minolta

- Mimaki

- ROQ International

- Seiko Epson

Bottom Line

Companies that plan to venture into the fabric printing industry need to identify the right technology that can cater to all the fabric printing needs. Brands can use stamp printing and transfer printing for smaller projects. Whereas, they can go for reactive printing or screen printing for larger projects.

Moreover, fashion brands that are facing challenges on the supplier front should turn to Fashinza for solutions. Fashinza is a reputed name that has become a one-stop destination for all supplier-related problems. Connect with them today and become one of the top players in the market.