Enterprise Resource Planning: A Hidden Arsenal for Fabric Mills

It’s been just 8 months since I have stepped into this fashion industry. Still, based on my limited understanding, I would like to share my experiences of dealing with the fabric supply chain and how we can optimize it through consolidated efforts.

I would share a couple of anecdotes of dealing with different stakeholders in the fabric value chain and then we will see how those processes could have been optimized through the use of Enterprise Resource Planning(ERP).

3rd April, my first visit to Surat, we went there to buy some stock fabrics, so that we could reduce cost and fabric delivery time for our future orders. To speak about the root cause of doing this exercise was that the mills didn’t have any method or infrastructure for on-demand visibility and live inventory status of ready prints. If we ask any supplier to send ready prints, in most of the cases, we get swatches with no details written on it, and by the time we show those swatches to the brands that fabric print gets sold out by the supplier and we have no visibility of how much quantity is available on a particular date. If we would have gotten the live visibility of their inventory, there would be no need of meeting the supplier physically, instead, customers like us could take informed decisions and share the details with the brands across the world in one go.

On my way to Jaipur, I got a chance to interact with the owner of a garment factory. He has a garment factory in Noida and a Fabric Mill in Jaipur. One of the pain points that he addressed was that he has no transparency of his mill in Jaipur, because of which he himself has to visit the factory regularly. Like, how much of the production has happened in a day against a fabric order, how many machines are occupied, how many are free, what is the status of the raw materials, at what point he should reorder the raw materials, how he can show live inventory of his ready prints to different customers.

Through this interaction, I came to understand that these pain points are interlinked with each other. Let’s raise a question at this stage: Can we get the live inventory status of ready fabrics by having a collection of finished fabric images and updating the quantity manually each time a supplier sells the fabric to their customers? The answer may be yes for the short term by deploying an extensive workforce but in my view it is not sustainable and scalable until and unless we digitize the entire value chain. Also, we have to understand that a fabric mill can capitalise not only on finished fabrics but also on excess intermediates and raw materials. That’s why it is very necessary to have the complete visibility of the entire value chain.

Let’s see an ERP architecture which fabric mills can adopt for improved coordination within the factory and with the customers, better utilisation of factory resources, wider accessibility of its products, better visibility with real time update of information.

Customer Details

There are multiple logistic activities that happen before an order is finalised. Most of the fabric suppliers I have dealt with do not have a digital database of their customers, as a result of which for all small activities like delivery address for sending swatches, PI details, all these details are asked multiple times on whatsapp. Through this feature, the fabric suppliers will be able to make a digital database of all their customers which can be used in swatch logistics, PI creation, categorisation of customers basis volume of orders ongoing, risk associated with a particular customer basis total cancellation/payment numbers, customer point of contact details etc.

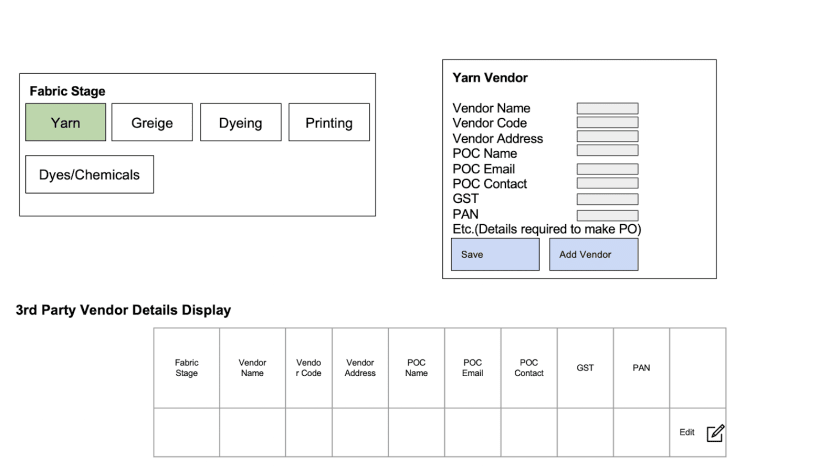

Vendor Details for raw materials and Service Orders

Every fabric supplier procures raw materials(yarn/greige/RFD/Dyes/Chemicals) from third party vendors and give service orders (like weaving/printing) to their own sub-workstations(in case they own a weaving or printing unit) or give it to the third party vendors. Now, to streamline this process of procuring raw materials and giving service orders, it is very necessary that the fabric suppliers have a digital database of all their third party vendors. So that, once an order is received and BOM is made they can just select suppliers from the list and all the purchase and approval documents are sent automatically to the respective persons with notification alerts.

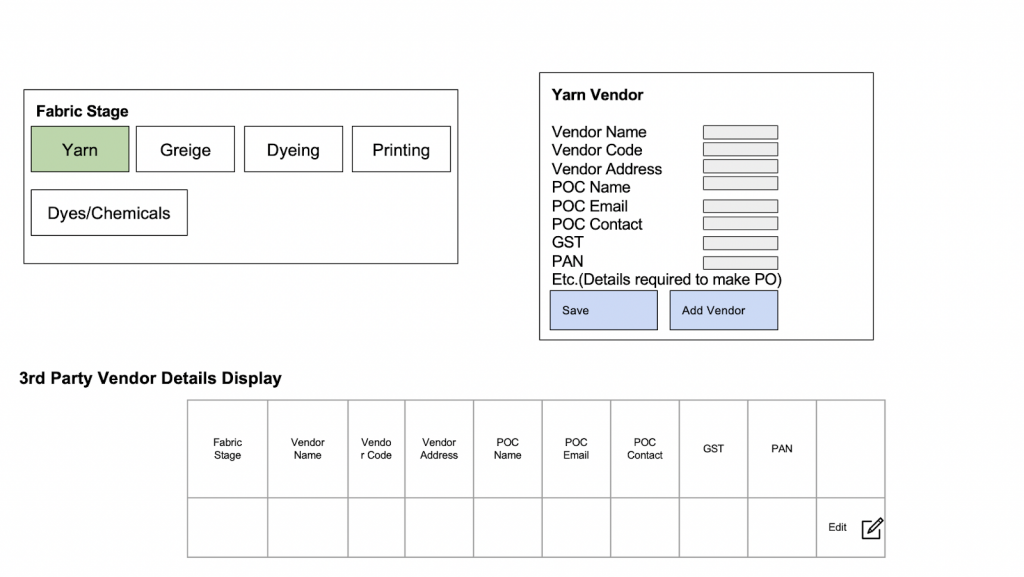

Mill Details

Details of all workstations (weaving unit, dying unit, printing unit, Finishing and Packing Unit, warehouse unit), number of machines in each workstation, workforce details involved in each workstation will help better planning of orders, coordinations among workers and business heads, faster response due to notification alerts to the respective worker on quality issues, production quantity track record for each day etc.

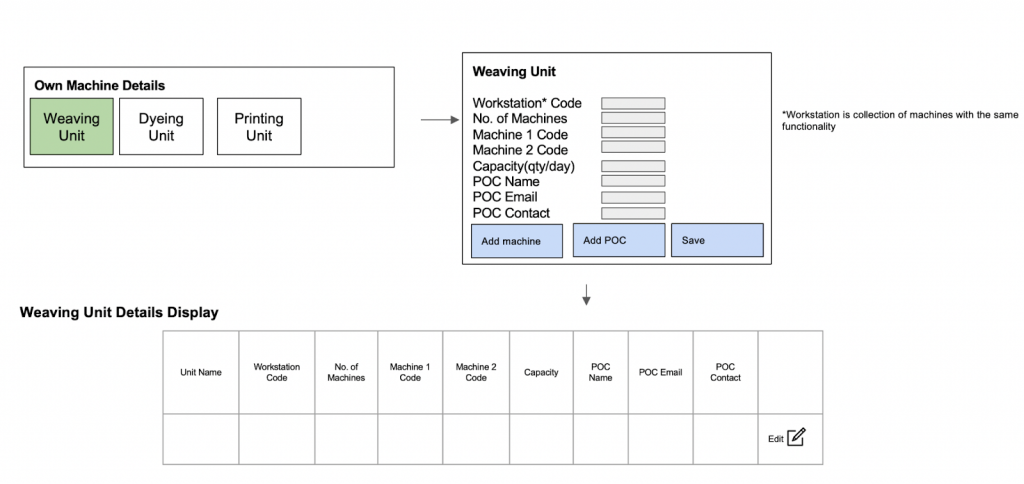

Fabric Quality Offerings

Suppliers can show the list of all the unique qualities that they are capable of providing. All the details including the current price range, MOQ for different types of printing, and lead time can be made transparent to the customers. Along with that, a supplier can attach sustainability certificates. This transparency will enable informed and fast decision-making for customers.

Fabric Print offerings

Every time a print comes out of production in it’s factory or is sourced by the mill from the third party vendor, the supplier can enter all the details of that print (image, fabric details, order id against which it is ordered/produced, stock purpose, workstation where it is produced/third party vendor from where it is sourced). This will help the supplier maintain an inventory base of all the prints produced/sourced by them. A supplier can also decide which prints they have to make public to all the customers (in case they have produced excess qty or produced/sourced for stock purpose )and which it has to hide (in case a print is already sold to the brand).

Now, one may think here that why not just make a website displaying all the print images and display the stock quantity against them manually. That is certainly a solution if you are dealing with fewer SKUs and fewer customers. But, if we want to go for live updation of information then any selling should happen through the platform itself. Like suppose, 5 brands have selected a particular print and they want 5mtr yardage for sampling purpose. Now, as soon as they buy from the platform, the platform will show the updated qty that will be 25 mtr less. One major benefit of digitizing the entire value chain is that a supplier can analyse which print is getting more traction, and since he will have the mapping of raw materials with that print id, he can start planning in advance if a particular print is selling fast. Additionally, if the print goes out of stock then he can show the greig quality to the supplier mapped with that print which can be printed in a certain time period (To give this data of time period, a supplier must have the visibility of the factory that what machines are free, what greig qty is available with him). That’s why a complete end-to-end visibility is necessary.

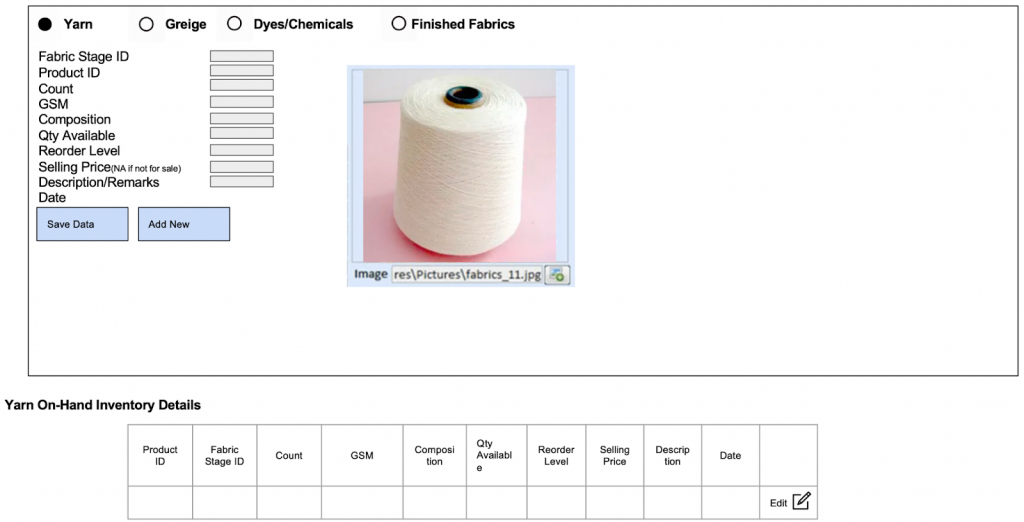

On-hand inventory details

Here a supplier can list all the raw materials (Yarn, Greige, RFD, printed fabrics) that are in surplus and which they want to sell.

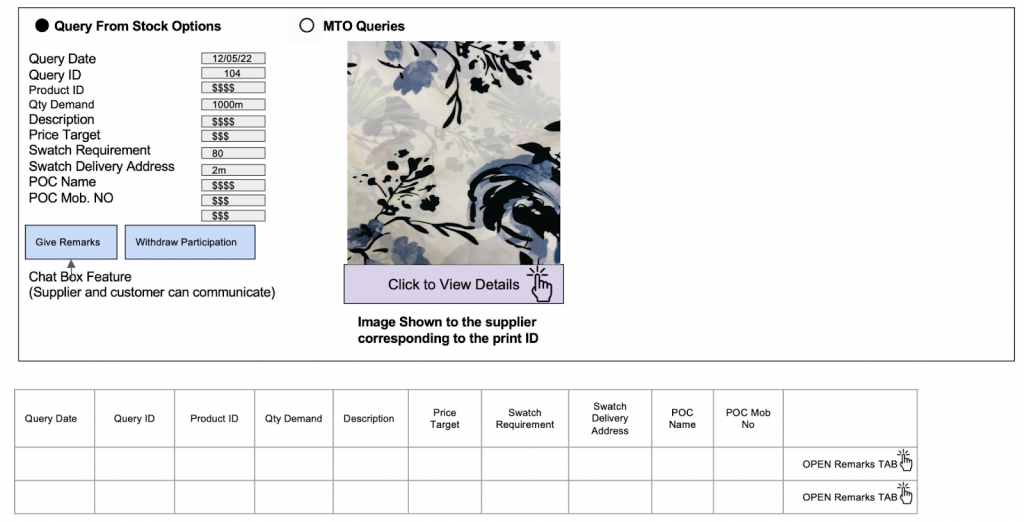

Customer Queries

Through this feature a supplier can see all the fabric queries from all their customers at one place, and instead of coordinating over calls and mails, they will get a central platform for communication. They can track whether a particular query is at the sampling stage, Lab dip stage, or bulk production stage.

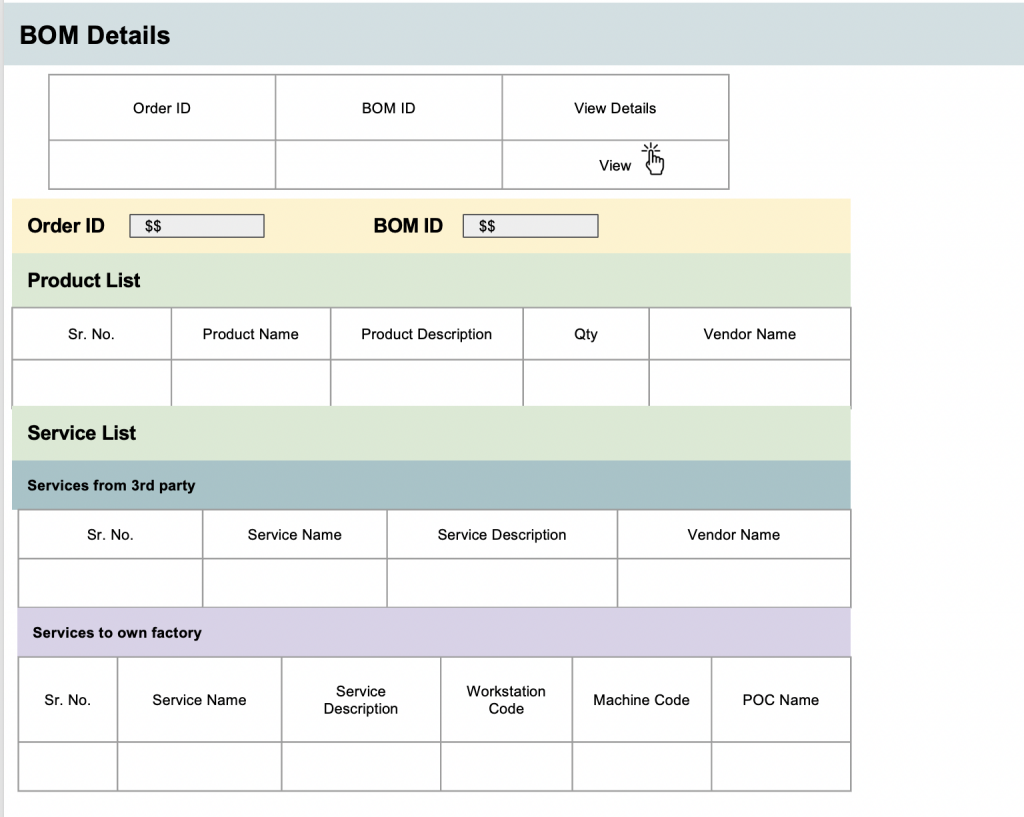

Order to BOM preparation

Once an order is finalised, the supplier can create the bill of materials that is required to complete the order. Once this mapping is done, it will be stored in the database and can later be used for automatic creation of BOM for the same type of orders.Once the BOM is made, the system will automatically show the list of 3rd party vendors corresponding to the raw material and process unique id. And then, a supplier can raise PO/Work Order to 3rd party vendors or to its own workstation. All the machine assignments, POC assignment, material requirements will happen at this stage.

Order Status

Through this feature, a supplier can track the production progress of each order. Which machines are occupied for which order, how much production is happening in one day, etc.

Conclusion

Implementation of this kind of ERP architecture can solve the twin challenges of globalization and fast fashion. Firms like Fashinza who have a large network of customers across the world will get transparency and live updates on the stock quantity of finished fabrics and unutilized resources of the factory in terms of raw materials and machine occupancy. Fashinza and other customers will no longer have to deal with multiple fabric suppliers over call. They can simply go on the platform and put their query and all the network of suppliers can respond to that query.

Fabric mills should start changing the traditional way of relying on physical meetings for selling their fabrics, rather they should contribute in creating a tech-enabled scalable and sustainable supply chain that has a wider outreach to customers in the shortest possible time with the lowest possible hassle.