What is Neoprene Fabric Made up of?

You must have watched TV commercials advertising sweat slim belts. They always talk about neoprene rubber or neoprene fabric, which uses modern technology to keep the sweat within. You must have wondered what this fabric is and how it works. Let’s discuss a few things about the composition, usage, and qualities of this neoprene fabric.

When chloroprene is polymerized, it produces polychloroprene. Neoprene is produced through this process of free-radical polymerization.

Neoprene rubber was first created in 1930 and is used in tires, wetsuits, hose pipes, etc. This was the first successful synthetic rubber created by human beings. Recently, designers have taken notice of this fabric and since it can provide the necessary warmth, it is used in jackets, wetsuits, etc.

Salient features of Neoprene fabric

1. Neoprene fabric is not breathable.

2. It has high heat-retention abilities.

3. Neoprene does not have any moisture-wicking abilities; this means it does not take away sweat from the body but keeps it inside. It doesn’t soak sweat as cotton does.

4. Neoprene fabric has high heat retention abilities.

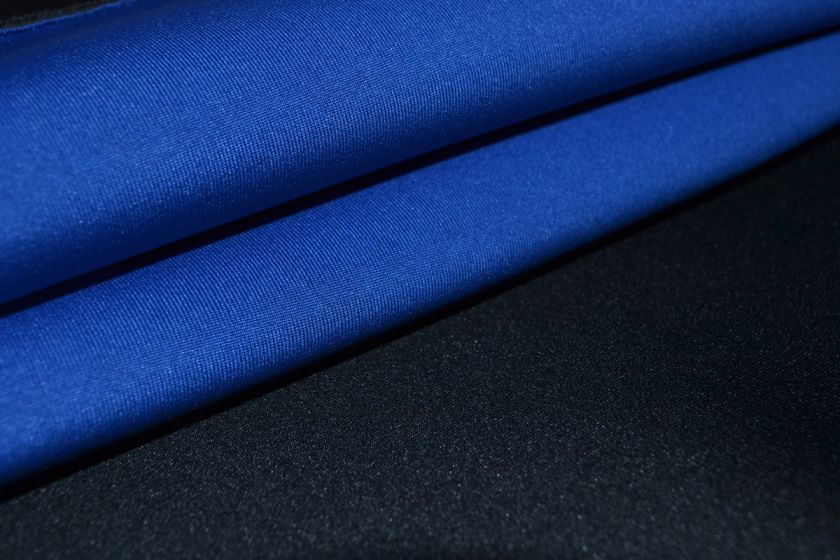

5. It is highly stretchable and hence is known as scuba fabric. It is the most popular wetsuit material used by scuba divers and marine experts. It is also a popular swimsuit material.

6. The material is prone to bubbling to quite an extent.

7. This fabric should never be washed in hot water. It is advisable to wash it in cold or lukewarm water (not more than 80 degrees C).

8. This material was first produced in the USA - DuPont Corporation, which remains the largest producer and exporter of this fabric to this day.

9. Neoprene fabric is not biodegradable.

Materials and Process to Make a Neoprene Fabric

Neoprene is a petrochemical substance, and it is extracted from petroleum. Using the free-radical emulsion polymerization process, natural chloroprene is transformed into a synthetic form which is known as polychloroprene. Polychloroprene is the base material for manufacturing neoprene fabric.

Neoprene material can also be obtained from limestone. Since petroleum and limestone both are non-renewable resources, manufacturing neoprene is not environment-friendly.

1. Delivery in liquid form: Polychloroprene, which is the primary element for manufacturing neoprene fabric, is delivered to the textile factories in liquid form. It is combined with chemical compounds to increase the elasticity of the product. Textile companies have their own patented formulae to add other chemicals to highlight other traits in the fabric.

2. Making the loaf: This mixture is then placed in a mixer and processed further. During this process, it is baked in an industrial oven and converted into a loaf similar to a bread loaf. It is this hardened chloroprene rubber, which is known as ‘loaf.’

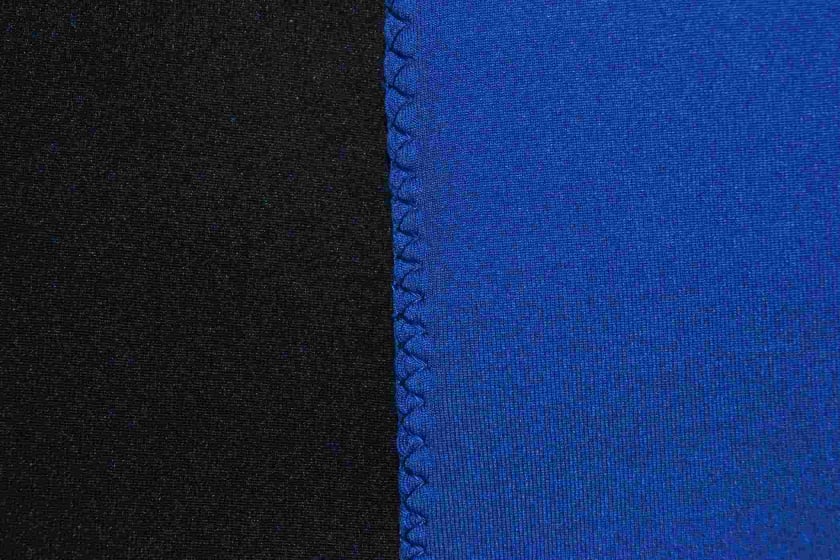

3. Slicing: Just like a bread loaf, the neoprene loaf is sliced using a large industrial machine. The average thickness of each slice is between 3 mm and 5 mm. Thicker polychloroprene sheets have more insulative and water-resistant properties. Since the pressure is higher in the deep sea, the diving suits that deep-sea scuba divers and snorkelers wear are normally made from 6 to 7 mm thick wetsuit material.

4. Embossing the patterns: The sliced wetsuit material then is loaded onto pallets, which in turn is shipped to the apparel manufacturing unit. In polychloroprene slices, patterns are then traced and the fabric is cut into slices, which are sent to the production unit for sewing. This is the final stage of manufacturing the finished material for this fabric. Multiple items can be made from a single slice. Tailors cut the required shapes as per their requisite measurements from the same slice.

5. Stitching: As per the orders received from the end customers, the wetsuits, sportswear, etc., are stitched in the production unit and packaged to be delivered. At this stage, fireproofing or waterproofing sprays are applied to the neoprene fabric.

Where Else is Neoprene Rubber Used?

1. Apparels: Jackets, women’s summertime garments, sportswear, sports bras, etc., are made out of neoprene fabric.

2. Accessories: This neoprene material is used in electronics cases as it protects the equipment from scratches and abrasions.

3. Patient care: Knee braces, soft splint materials, wrist extension orthoses, neoprene knee sleeves, etc., use medical-grade neoprene material.

4. Military applications: Military-grade neoprene rubber is used in multiple products like tanks, fueling stations, submarines, vessels, under tanks for transport, truck beds, and other war equipment. Gaskets are used for providing insulation to soldiers in extreme weather conditions. Wetsuits made of high-grade neoprene rubber are used by navy officers across the globe for underwater activities. Neoprene fabric is also used in engine cowls, seals, hose pipes, weapons repair tables, helicopter maintenance, machine shops, and workstations. Since this material is resistant to greases, solvents, and oils, it becomes very valuable for multiple types of equipment for the military.

The technology for manufacturing neoprene rubber has evolved a lot over the years and in the future, this fabric is expected to be used in many other industries.