Five Ways to Reduce the Carbon Footprint of the Fashion Industry

Clothing production almost doubled in the first 15 years of the century, while the number of times a garment is worn before being discarded decreased by 36%. Meanwhile, the UN estimates that around 10,000 litres of water are required to grow one kilogram of cotton, which is in turn needed to make just one pair of jeans.

The above statements are just the tip of the iceberg. Let’s look at some statistics published by the UN Environment Programme (UNEP):

- The fashion industry is the third-largest contributor of global carbon emissions – responsible for between 2-8% of global carbon emissions.

- The global apparel industry consumes around 215 trillion litres of water a year.

- Textiles account for about 9% of annual microplastic losses to the oceans.

- The global apparel industry emits over 3.3 billion metric tonnes of greenhouse gases annually, much more than the amount emitted by international flights and maritime shipping combined.

These figures should undoubtedly concern the entire textile industry, particularly the fashion industry.

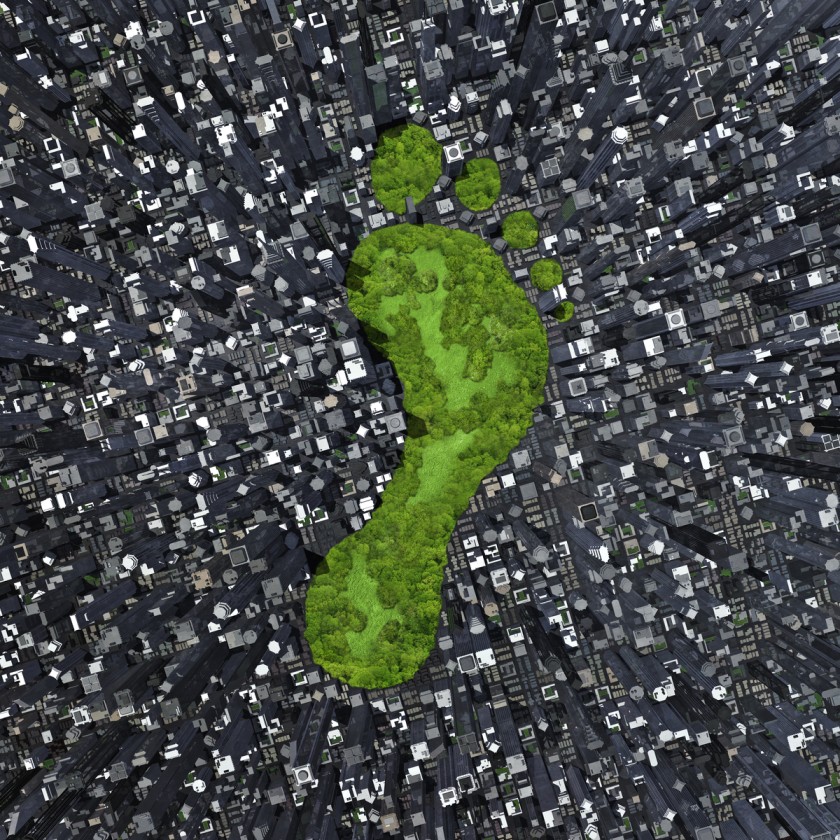

What is a carbon footprint?

A carbon footprint is the total greenhouse gas emissions caused by an individual, event, organisation, service, place, or product, expressed as a carbon dioxide equivalent. A carbon footprint can increase due to the emission of greenhouse gases, which may result from any of the below sources:

- Fossil fuel combustion for energy

- Landfills, coal mines, and oil and natural gas operations

- Agriculture

- Industrial waste and gases

Types of carbon footprint

According to the Greenhouse Gas (GHG) protocol corporate standard, greenhouse gas emissions are classified into three scopes:

- Scope 1 emissions are direct emissions from sources owned or controlled by an organisation. An example of this is fuel combustion.

- Scope 2 emissions are indirect emissions generated due to the purchase of energy, such as electricity, heat, steam, etc.

- Scope 3 emissions are indirect emissions (not included in Scope 2) that occur in the value chain of the reporting company. It includes upstream and downstream emissions such as transportation, waste generated during operations, purchased goods and services, etc.

How does the fashion industry contribute to the carbon footprint?

According to a report by Mordor Intelligence, the global apparel market is likely to record a compound annual growth rate of 5.5% during the years 2020 to 2025. This anticipated growth can significantly increase the carbon footprint.

The carbon footprint of the textile industry can be estimated based on the energy consumed during the manufacturing of the fabric/product. The carbon footprint can increase due to any process in the entire supply chain cycle of the textile industry. There are seven stages in textile production, from raw material to finished goods. During each of these stages, a large part can contribute to an increase in carbon footprint.

Stage 1: Fibre production – At this stage, significant energy is consumed through electricity, water, chemicals and the fuel used for machinery.

Stage 2: Yarn production (spinning the harvested fibre into yarn) – This uses machines, which consume fuel, water, spinning oils, and electricity.

Stage 3: Fabric production – At this step, sizing chemicals, solvents, adhesives, binders, and lubricants are added to prevent the yarn from breaking during the processes, such as knitting, weaving, etc.

Stage 4: Pre-treatment – Once the fabric is ready, it undergoes pre-treatment to accept dyes and functional chemicals. The pre-treatment process involves washing, de-sizing of sizing chemicals, bleaching, etc.

Stage 5: Dyeing – The dyeing and printing of fabric uses hazardous chemicals, dyes, plasticisers, detergents, etc.

Stage 6: Finishing touches – The sixth step is about providing finishing touches to the fabric. Depending on the style of the fabric, chemicals, resins, oils based on fluorocarbons, polymers, etc. are used.

Stage 7: Logistics – The final step involves the manufacturing, transportation and retail sales of the finished fabric. At this step, the fabric is shaped into clothes and other utility items by providing desired colours and designs. It means extensive use of water for washing and dyeing the fabric, using chemicals for colouring, biocides for protection against mould during transportation, and plastic for packaging purposes.

Out of all the above processes, the dyeing and finishing stages account for the highest greenhouse gas emissions from the fossil fuels required to generate heat and electricity used during these processes.

While the carbon footprint can increase due to the entire manufacturing life cycle of the fabric, there are a few significant contributing factors that can further increase the carbon footprint from the textile industry:

- Changing fashion trends – With access to multiple brands, consumers have become picky about their purchases. This has encouraged clothmakers to introduce new trends in the fashion industry more frequently.

- Reduced lead times – Since fashion trends change frequently, there is a constant race to supply in-trend designs before the trend fades. This leads to higher utilisation of transportation, which in turn increases greenhouse gas emissions.

- Change in consumer prices – Reduced prices on clothing lines have encouraged wardrobe makeovers for buyers. This results in higher demand for clothing products on offer resulting in a higher supply of products.

- Packaging – Plastic packaging accounts for 50% of plastic waste. The higher thenumber of products manufactured, the higher the plastic consumption in packaging.

- Disposal – As clothes reach the end of their life cycle, a lot of fuel is used for their disposal. This is due to the fuel needed for transportation to landfills and incineration centres. The process of incineration itself demands a lot of fuel consumption.

5 ways to reduce the carbon footprint in the textile industry

Now we know how the textile industry is contributing to increasing the carbon footprint, let’s look at the top 5 ways to reduce the carbon footprint in the textile industry:

- Recycling: Recycling/repurposing of finished products will decrease greenhouse gas emissions as it will eliminate a lot of processes throughout the various stages of textile production.

It will also result in lower utilisation of resources that cause greenhouse gas emissions. Attire makers have already migrated to creating fashion lines through recycled plastic. For example, Adidas has designed and manufactured uniforms for the Real Madrid football team using recycled plastic salvaged from the oceans several times in the past few years. Similarly, the Sri Lankan cricket team’s uniform for the 2019 Cricket World Cup was upcycled through plastic waste recovered from the beaches of Sri Lanka.

- Moving to alternate sources of materials: Traditional fabrics such as cotton and silk have a considerable adverse effect due to the processing required for their preparation. Focusing on using materials like biodegradable fabrics, wood and forest-based fibres, clothes that decompose better and have a lesser impact on carbon footprint will also help create a sustainable trend in the industry. For example, organic cotton offers a 91% reduction in freshwater withdrawal from lakes and rivers.

- Process enhancement: During the multiple stages of textile production, the use of alternate resources can positively impact the carbon footprint as well as greenhouse gas emissions. For example, using different oxidising agents during the bleaching process can result in a shorter bleaching time as the process can be carried out at lower temperatures. It will result in reducing the carbon dioxide emissions from the process. Another benefit of the shorter bleach time is the reduced use of finishing chemicals as the fabric will be softer, thereby reducing the overall carbon footprint.

- Enabling the supply value chain: There are many micro, small, and medium-sized enterprises (MSMEs) that are part of the supply value chain in the textile industry – from suppliers of raw materials to manufacturers of dyes and chemicals. Support by stakeholders at all levels (from farmers to manufacturers to fashion designers to fashion labels) in the industry for these MSMEs in reducing the carbon footprint is essential. It is possible by partnering to improve processes; for example how fibres are grown, spun, treated, dyed, manufactured and ultimately sold at retail outlets.

- Adoption of new technology: With the advent of new technologies, it is possible to reinvent the entire life cycle of the fabric. For example, low liquor ratio dyeing machines have a lower water consumption rate when compared to the older winch machines. The lower energy and chemicals consumption results in greater productivity as the process is more efficient and accurate.

By using different software, the industry can crowdsource ideas for design. Furthermore, the demands can be linked directly to production and the supply chain to manufacture small batches of the fabric. Also, technology can be leveraged to manufacture and produce fabric with a longer shelf life. Implementing technology at stages can significantly help reduce the carbon footprint for the textile industry.

The release of greenhouse gases and increase in carbon footprint is an inevitable part of the entire life cycle of fabric to cloth in the textile industry. However, the industry can take conscious steps to reduce its carbon footprint and move towards more sustainable and environment-friendly processes and materials.