Explained: Foam Dyeing from Start to Finish

Colors attract customers to buy apparel and textiles; this is what makes the art of dying clothes more than just a process. In today’s world, fossil fuel consumption has increased dramatically due to improvements in many industrialization processes to cater to the needs of an increasing world population. A few manufacturing processes involving dyes have had a significant impact on the environment, resulting in excessive health risks and the threat of global climate change! With chemical dyes and old methods come a high concentration of nitrous oxide, methane, carbon dioxide, chlorofluorocarbon, etc., which has negatively impacted the planet’s water and energy resources.

The textile dyeing industry is no newbie to technological changes, with a variety of new dyeing methods being developed. There is an urgent need to introduce new detergents, new kinds of fabrics, and new methods to replace harmful and conventional dyes. Another important factor in this change is seasonal variation and demand.

Keeping all this in mind, one of the best additions to the textile dyeing industry is the foam dyeing process. This new method paves the way for a sustainable and effective dyeing process.

For a deeper understanding, let’s look into the step-by-step process and the brief advantages of using this cloth dye method.

What is foam dyeing?

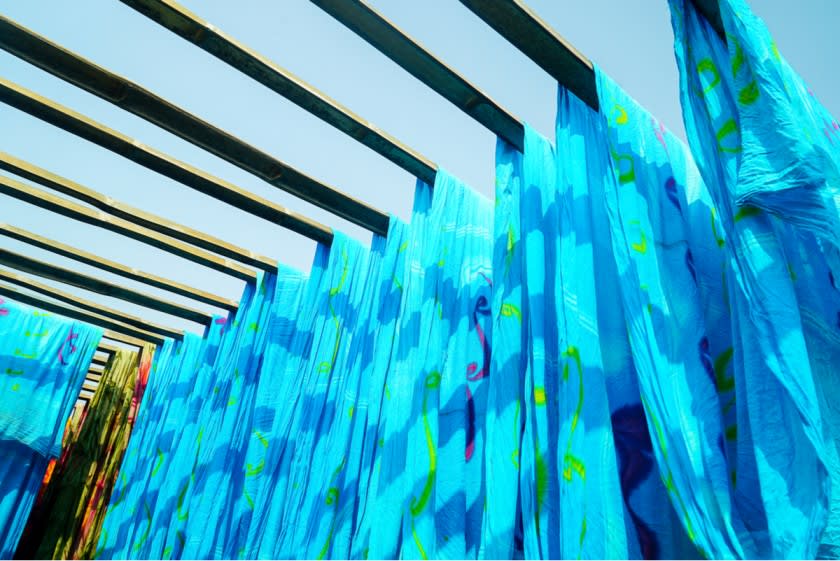

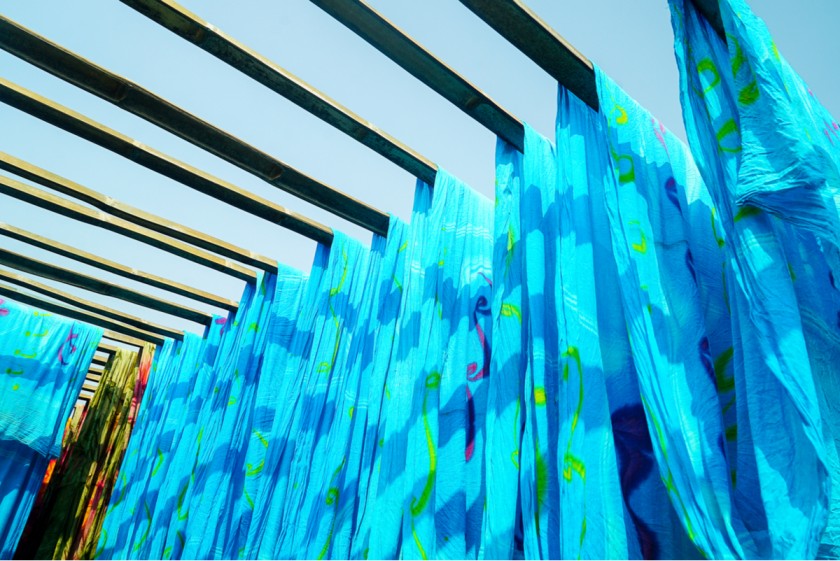

Let’s start from the basics! What exactly is foam dyeing? Foam dyeing is an alternative to the traditional cloth dye methods that are a potential environmental and supply chain hazard. Just as the name states, this process uses foam instead of water to carry the dye or chemicals over the fabric.

There are two types of foam processing: continuous wet processing and continuous foam processing. In the conventional continuous wet processing method, the fabric is immersed in a huge bath containing a tiny solution of dyes and chemicals. The saturated fabric is passed through squeeze rolls that extract excess solution before it is transferred into an oven to dry the fabric.

In the continuous foaming process, the chemical dyes are formulated with a foaming agent that is more concentrated. The mechanically formed formulation increases the dispersion‘s volume by 5 to 20-fold. This foam is then applied as a coating to the fabric and passed through squeeze rolls to distribute the solution uniformly throughout the fabric. The fabric is then put into a drying oven, just like the previous method, but the water quantity that needs to be evaporated is just 15 to 35%.

The foaming agent used in the process must be able to generate foam instantly and offer a good moist condition. Apart from this, it should give a uniform vetting action without impacting the quality. The agent should also be compatible with other elements like the final solution and not be affected by water hardness. Moreover, it must not cause the yellowing of white materials and should produce the required bubble sizes according to your preference.

The process of foam dyeing

Step 1: The process involves pre-washing the fabric to remove any dirt or oils that might be on it.

Step 2: The required quantity of soda ash is dissolved in hot water depending on the length of the fabric. The fabric is then soaked in this solution for about 5 to 10 minutes and dried.

Step 3: Next, dye powders are dissolved in warm water and stirred to form a very smooth paste. The foaming agent is then added to the dye solution and beaten until it becomes creamy and thick.

Step 4: The mixture is poured onto a tray, in a pattern, with a tool that spreads and swirls the dye however you like. The remaining air bubbles are removed by a gloved hand or a tool, and the fabric is allowed to dry for another 5 minutes.

Step 5: A flat surface is then placed on the fabric with the foaming side up and is left to sit for another 2 to 24 hours to develop the dye. Until it develops, the fabric needs to be in a moist condition for the activation to take place.

Step 6: After this, the fabric is released into cool water to remove the soda ash, and the temperature is increased massively. Continuous rinsing is performed until the water is almost clear.

Step 7: After 30 minutes, the machine's temperature is raised to 90°C, or whatever the ideal temperature, which is based on the type of fabric and the selection of dye. This entire cycle goes through another sequence of operations like rinsing, dyeing, finishing, centrifuging, and drying.

Step 8: Finally, the fabric is dried and pressed, and your foam-dyed fabric is ready!

Advantages of foam dyeing

Foam dyeing has a lot of advantages, and here are a few of them:

- Over the years, various procedures have been developed where foams are used for dyeing. The recent process ensures that foam can be applied on the fabric surface with uniform distribution and can penetrate even to the interior parts of the fabric.

- Unlike other dyeing processes, foam dyeing technology is not a hazard to the environment. This process helps reduce environmental pollution and excessive solid waste.

- This process provides improved migration and prefixation into the fibers with abstract color yields in a shorter period of time.

- It is an energy-conserving method, unlike the conventional wet dyeing of textiles. Over 75% of the water needed for chemical dyes can be done away with the concentrated mix that foam dyeing technology uses.

- It requires very less consumption of chemical agents per unit of textile, as foam dyeing provides a seamless distribution with ease.

- It saves 50% more energy and reduces petroleum cost and consumption by 10 to 40%.

- Foam dyeing reduces the loss of fiber strength, thereby improving the quality of the final product.

- Various types of finishing chemicals can be applied simultaneously to both sides of the fabric, even with high GSM.

- Dyeing with this method can shorten the length of the device, plant size, and lessen the amount of investment.

Form dyeing technology is not hard on the environment as some of the other dyeing processes. It provides improved type prefixation and migration to give you superior color yield and helps improve the dimensional stability of the fabric. It is also more energy-efficient compared to the conventional wet process of dyeing, printing, and finishing.

The water that is ordinarily used to apply chemicals or dyes to the fabric can be reduced up to 75% with the concentrated mix procedure that is implemented with the foam dye process. Here, air serves as the dispersing medium instead of water, creating ideal foam and uniform distribution of ties throughout the fabric. The use of foam dyeing has also doubled the line speeds and has reduced the consumption of chemical agents for the unit of fabric. Depending on the construction of the fabric and fiber composition, about 70 to 100% of the weight of the fabric is just water, which is evaporated in the oven.

Even before we had an energy crisis from 1973 to 1974, a lot of efforts were made to reduce the water consumption in the garment processing industry because of the decrease in quality water and increasing costs of disposing and treating wastewater. Traditional methods or wet pick-up systems have always had great difficulty in distributing low amounts of dyes or chemicals in a large area of fabric. Foams have overcome all these problems!

As foam processing uses concentrated liquid, and the volume is increased through the air, uniform distribution of dyes over the fabric occurs, assuring quality. The form meted inside the fabric can also be removed and recycled.

Application of foam dyeing in the fashion industry

Many major fashion brands have started to dye their products using foam dyeing technology. For instance, IMD (Indigo Mill Designs) introduced foam dyeing technology for denim at Texas Tech University. The early investors of this technology are Lee, Wrangler, and Walmart. Using this method, the company reduced energy and water usage by more than 90%, while producing equal or even better dye quality as compared to the previous dye process. This technology also allowed manufacturers to make the fabric in smaller quantities, thus reducing water and fabric waste.

By using this technology, the Wrangler project conserved about 8 billion liters of water annually. Together with Lee Cooper, the suppliers are set to save at least 17 billion liters of water each year.

Conclusion

Foam dyeing methods have caught the attention of the cloth dye industry with their hassle-free techniques and conservative operations. They use foam instead of water to transfer the dyes and chemicals to the fabric, resulting in minimal drawing operations, thermal operations, and energy consumption.

If you are a clothing brand that wants to manufacture its collection using the foam dyeing method, finding the right manufacturer can be a bit of a challenge. That is why Fashinza provides you with a platform that connects brands with suppliers to manufacture the collections in a hassle-free process.

Our platform handles everything from ordering, tracking, communication, payments and even provides you with daily updates about the production. Now your brand can also provide quality and sustainable dyed clothes while conserving the environment!