Supply Chain Integrating—Get Rid of the Bottlenecks Today

Summary: Various supply chain bottlenecks threaten your business if you aren’t careful. To avoid and resolve these bottlenecks, integrating your supply chain with the latest fashion technologies is the best way forward. Here’s how supply chain integration will benefit your business and get rid of bottlenecks.

Has your supply chain been facing unforeseen issues? The problem lies with unidentified supply chain bottlenecks and a lack of supply chain integration methods using modern technologies. If you wish to avoid issues such as increased cost of production, labor shortages, discrepancies in shipments, faulty production of orders, and more, you’ve come to the right place.

Find out what are supply chain bottlenecks, how to identify them earlier on, and how to resolve them using supply chain integration.

What Are Supply Chain Bottlenecks?

Supply chain bottlenecks are identified as any hiccups in the supply chain that cause an unprecedented increase in production costs and make businesses lose precious time in completing the manufacturing and delivery of product orders. For example, the pandemic brought about many supply chain bottlenecks when it comes to transporting products and raw materials, availability of labor, strict trade laws and more.

How Can Fashion Companies Get Rid Of Supply Chain Bottlenecks?

Supply chain bottlenecks can be resolved by opting for a more integrated supply chain model and using advanced fashion technology solutions to navigate through congestions in the manufacturing process. With supply chain integration, fashion companies can tackle bottlenecks much more easily and promote the smooth functioning of business right from order placement to delivery of finished products.

What Is Supply Chain Integration?

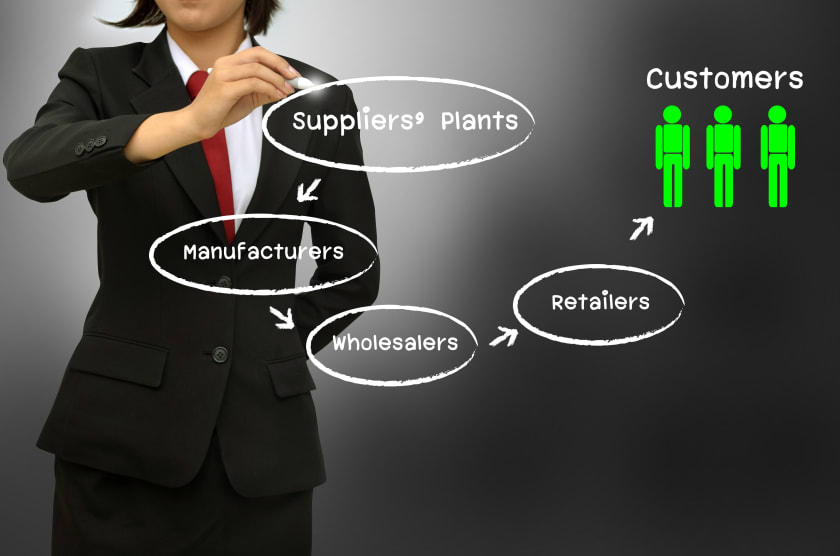

Supply chain integration is a business strategy that ties various links of the supply chain together in a closer working model to ensure a smooth production process and improve order turnover time. With supply chain integration your fashion brand can control costs of production, reduce waste, and tick off essential production stages in a time-efficient manner. An integrated supply chain will help get rid of bottlenecks and make business boom. Supply chain integration can be best done with advanced technology solutions using Industry 4.0.

Best Ways To Resolve Supply Chain Bottlenecks With Technology

Creating a supply chain with Industry 4.0 solutions is a great way to easily resolve supply chain bottlenecks before or as and when they occur. Industry 4.0 is basically digitizing vendors, manufacturers and other stakeholders in the supply chain. With an industry 4.0-backed digital supply chain, smooth functioning on various levels of the production and delivery process can be achieved.

Here are a few ways how this Industry 4.0 technology can help with supply chain bottlenecks. Develop a supply chain data analytics strategy to make business much smoother.

Data Analytics

Opt for manufacturers and suppliers who are vetted and can provide data on the various production stages of your order. With data analytics that provide real-time updates, you can track your order and have a heads-up on delivery time for finished products. You can identify where the bottlenecks emerge and resolve them in a more time-efficient manner. Data analytics will also help you track shipments and understand consumer purchasing behavior so that you can make planned decisions when it comes to inventory.

Automation

Automation technologies will help secure an uninterrupted supply of products and will also improve coordination between various vendors within your supply chain. Automating your supply chain will reduce order turnover periods, reduce labor, promote better inventory management, reduce warehouse costs, and make your supply chain well-connected and tight-knit. Operations of heavy machinery which is usually dangerous can be automated so that it makes it safer for workers in manufacturing companies.

Paperwork like invoices, order documents and more can also be automated to accelerate order turnover time and stop the task of filing the necessary paperwork to delay the production process. Automation can also predict an increase in product demand and signal your company so that sufficient inventory can be maintained. Automation is also very useful in this day and age because Covid-19 restrictions such as social distancing and worker shortages due to the pandemic make in-person dealings a bit unsafe.

Simulation Modeling

Fashion companies can identify the root cause of bottlenecks in the supply chain with simulation modeling. Simulation modeling enables companies to identify and examine potential discrepancies in the supply chain so that they can resolve any potential bottlenecks before executing business processes in the real world.

Simulation modeling is a better alternative to identifying bottlenecks rather than manual assessments because manual assessments can easily lead to errors. Manual assessment errors lead to late identification of bottlenecks and therefore disrupt the supply chain functions.

The processing power of simulation modeling can be increased with cloud computing should you choose this method in your supply chain. Organizations can mimic countless fictitious scenarios with cloud hosting and then decide on practical methods to clear any potential occurring bottlenecks.

Conclusion

You are now equipped with the knowledge to tackle supply chain bottlenecks head-on and prevent them from disrupting your business. Integrate your supply chain with the latest Industry 4.0 solutions today!

Key Takeaways

- Data Analytics will help identify bottlenecks in the supply chain in real-time.

- Automation will ensure safer working conditions and also anticipate bottlenecks.

- Simulation modeling helps identify the root causes of bottlenecks and predict potential bottlenecks before taking the supply chain activities live in the real world.

Fashinza is an AI-powered fashion technology company that brings the best business solutions to fashion companies across the globe. Fashinza has a network of digitized manufacturers and suppliers to help make supply chain dealings a whole lot smoother and more efficient.

Head to Fashinza.com to help integrate your supply chain and get rid of potential bottlenecks in a safe and timely manner.