Top Futuristic Innovations In Cloth Manufacturing For This Decade

When it comes to changes in fashion trends, the changes in the manufacturing industry have been so quick. The fashion sector is considered to be the most exciting one. The changes in the production and manufacturing sector have modified the fashion world completely.

Due to increased competition and ongoing trends, it has become important to stand out. For this reason, many companies are focussing on the use of upcoming futuristic innovations in the clothing industry. All the retailers and manufacturers are also relying on these innovations for their development.

In this article, you will read about the various futuristic innovations that will be helpful for manufacturers, designers, retailers and consumers. You will learn about the various techniques and use of new technologies, which will help you create, modify, and launch your products. You will even learn about the various brands that are willing to adopt these innovative trends to meet their daily demands efficiently.

Below are the top 7 futuristic innovations that can be found in the cloth manufacturing area all around the world:

1. Entering into the AI world

The connection of the technology sector with the fashion world has turned out to be the best innovation so far. One of the main contributions is the use of Artificial Intelligence. With the help of this, the manufacturers involved in the production of clothing lines are able to study consumer preferences. Accordingly, the designers initiate the process of styling the product.

Moreover, artificial intelligence also allows you to have information relating to the type of material to use, the alternatives for out-of-stock items and recommending the styles for various body types, skin colour, etc. This innovation has surely been the best part of modern algorithms.

2. Supply chain optimization under the same roof

In a competitive world where everyone is competing for success, one sure element is customer satisfaction. To meet the constant demands of the customers, the manufacturers are focusing on the quick supply chain system. Bringing the entire operative functions under one roof from fabric selections, samples, technical designing to production and shipment is an effective strategy.

Another effective measure for optimization of the supply chain is “in-house” production. This ultimately increases the efficiency and speed of timely supplying of products to the end-users. Companies have started using multiple machines to quickly meet up the demands of the consumers.

5. Mobile E-commerce

Today’s era revolves around the concept of a digitized world where the ease of getting everything done online is a huge success. The most used digital device for the purpose of shopping is via mobiles. Various brands have their own mobile applications to reach out to their customers anytime and from anywhere.

Popular applications like Instagram, which come with the feature of shopping, have been an uplifting factor towards sales growth. Many customers can now shop online and pay via wallet options to get their products delivered to their place.

Manufacturers are likely to benefit from this the most as they are responsible for tying up the brands with the end consumers. With a huge social media presence, the growth of sales and profitability is amazing. Besides this, with mobile e-commerce, you can easily update yourselves with the ongoing trends too.

6. Keeping up with the Production Cycle

Due to high competition in the market, the demand for fashion products is increasing along with the changes in consumer preferences. To meet the expectations of the customers, the manufacturers are required to stay updated. For this, new technologies like data analytics have been of utmost importance.

With the help of data analytics, it becomes easy for the manufacturers as well as the designers to launch their products. This process is known as the made-to-order trend. Many popular brands such as Zara have opted for this innovative technique to speed up to meet their ongoing demands effectively.

Working digitally by making 3D samples of clothes, garments, etc., will help the retailers to place orders before manufacturing the products. This production cycle is an efficient way leading to a reduction in overstock and less clothing.

7. Online Vectors Designing

Before beginning with the manufacturing process, the most important thing to focus on is designing. To overcome the lack of creativity, you can rely on certain ‘online vector editors’, providing the best design base. These editors are a perfect one-shot solution for graphic designers or clothing designers to try their sample designs online.

Vector editors such as Repsketch provide you with clothing templates in various styles. You can easily pick any colour, along with different collar sleeves, and pockets to create your designs. Besides this, other vector editors include Adobe illustrators, Vectr, Boxy SVG editor, etc.

Such editors can be used on any machine and from anywhere. Once your sample designs are prepared, you can easily ask the manufacturers to produce these accordingly. How cool is that!

6. Digitizing Manufacturing in Digital Factories

The digital era of technology has been the greatest contributing factor to the growing fashion industry. With everything going digital, the futuristic innovation in the fashion world has introduced a new system of digital factories.

The future of digital factories consists of self-repairing and self-servicing structures. There will be minimal human intervention along with a fully integrated factory system. Everything will be automated, from real-time planning and data analytics to production and manufacturing.

Many companies will benefit from such innovation as they will be able to produce highly demanded customized products at low costs. Every functional area will be carried out automatically with a fully smart in-built system. All of this will lead to minimum overhead cost as well as the production cost.

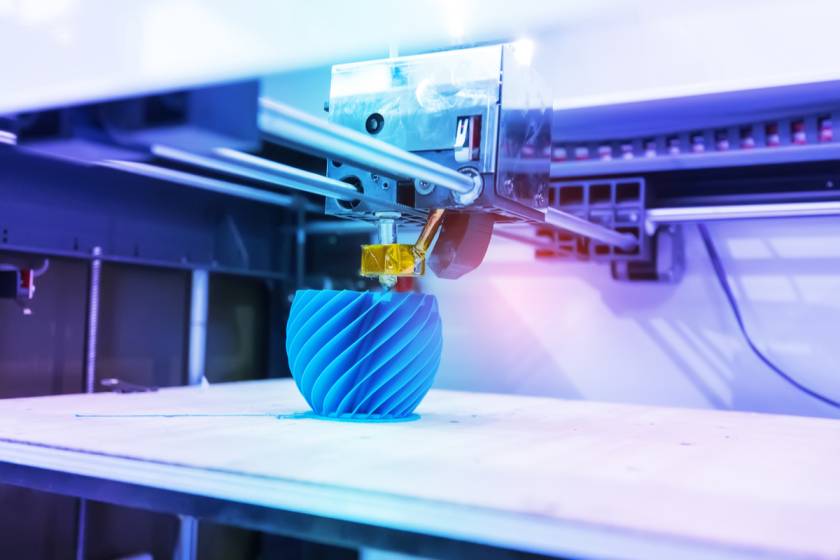

7. 3D Designs Printing

Many popular brands and companies are adopting the futuristic innovation of 3D designs. With this, you will be able to design your products in a 3D way as per the tailored needs of the customers. This is the best possible way to make the customized products available to the end-users.

Technologies like CLO and EFI Optitex allow you to edit the product designs instantly while considering the technical patterns. 3D design printing is the best strategy for on-demand production. With such printers, you can get your customized designs ready on the spot without any delays. Not only this, but this method reduces the use of fabric up to 35%.

Conclusion

Now we know the importance of innovative fashion and the different ways to effectively shape it to reflect its longevity. Such futuristic innovations ensure sustainability in the competitive world. Moreover, you can rely on these innovations for your future growth perspectives. The above mentioned futuristic innovations are likely to give you positive results in the long run. Not only this, but many companies will be benefitted while making their operations easier, like never before.

In order to know more about the manufacturers who are adopting these innovations, and are working on them, you can google about the company called ‘Fashinza’. This is a B2B apparel manufacturing platform that is responsible for connecting the manufacturers with suppliers. They provide you with a platform where you can easily place your orders, make online payments, and get your product delivered to your doorstep. Such manufacturers are using the latest upcoming techniques to update their way of working and effectively reach out to many people in a short amount of time.